201 Stainless Steel Solutions

201 Stainless Steel Manufacturer In China

201 stainless steel is an austenitic chromium-nickel-manganese alloy known for its cost-effectiveness, excellent formability, and reliable corrosion resistance.

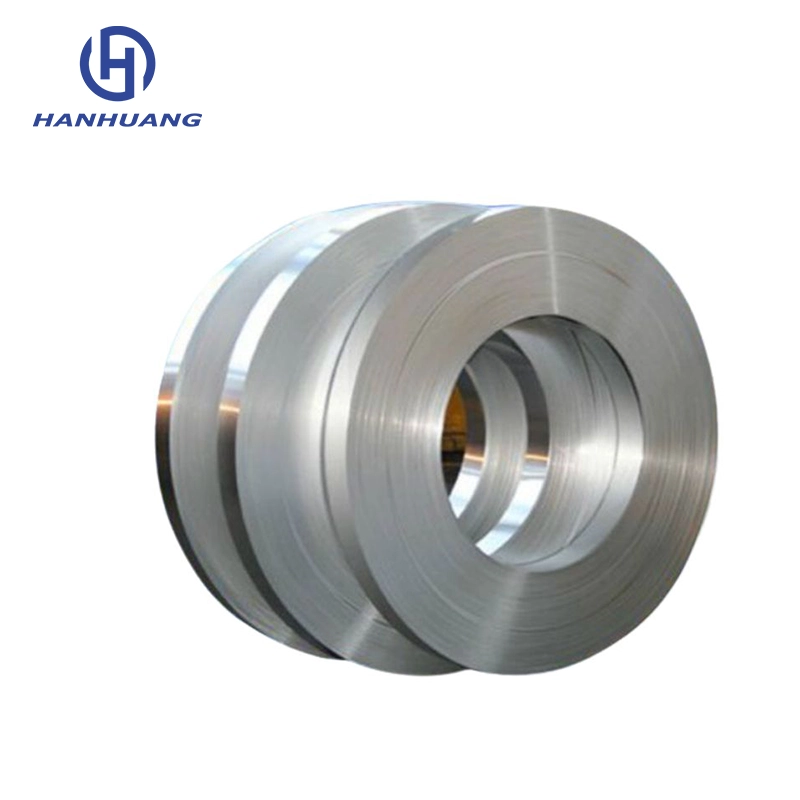

Widely used in industrial and commercial applications, Hanhuang 201 stainless steel supplier products protect machinery, equipment, and structural components from wear, corrosion, and environmental exposure. Our custom 201 stainless steel can be supplied in sheets, coils, strips, plates, or fabricated components to meet diverse industrial requirements, ensuring durability and performance across every application.

201 Stainless Steel By Shapes

201 Stainless Steel Heat and Corrosion Resistance – Hanhuang

- Heat Resistance

201 stainless steel maintains structural integrity up to 800°C in continuous service and up to 925°C intermittently. Prolonged exposure to high heat may slightly reduce corrosion resistance, but mechanical performance remains reliable. - Corrosion Resistance

Indoor Use: Excellent resistance to moisture, humidity, and light chemical exposure.

Outdoor Use: Suitable for mild environments; protective coatings recommended for long-term or coastal exposure.

Humid & Salt Spray: Moderate resistance allows safe use in industrial projects and wholesale applications, though 316 stainless steel is preferred for extreme conditions.

201 Stainless Steel Processing & Fabrication – Hanhuang

Forming

201 stainless steel offers excellent cold and hot rolling performance, with superior bending and stamping capabilities. Ideal for custom fabrication of industrial and architectural components.

Welding

Good weldability using TIG, MIG, or spot welding. Post-weld annealing restores corrosion resistance and relieves stress.

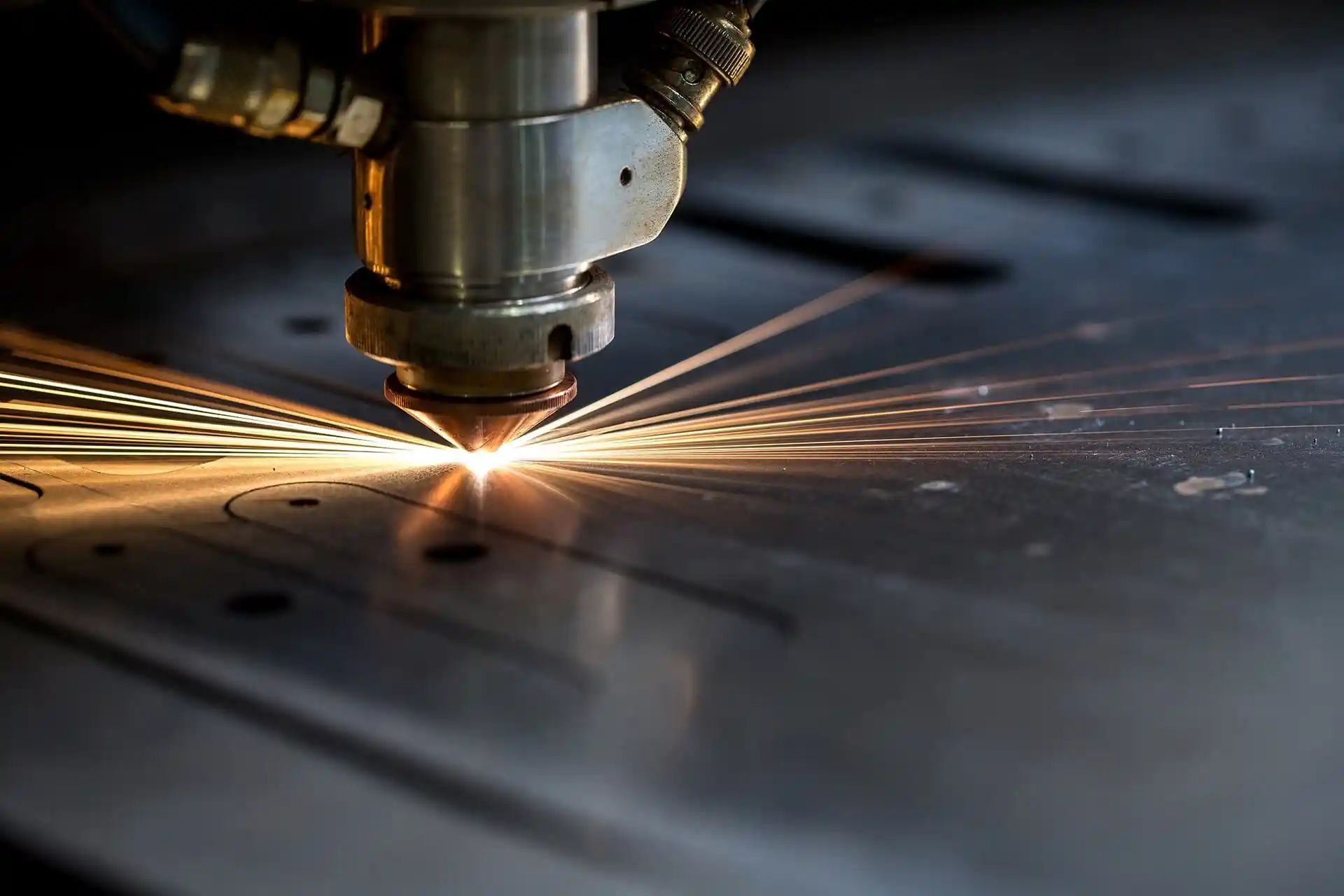

Machining & Cutting

Easily cut, drilled, milled, and turned. Slightly harder than 304 but maintains excellent machinability for 201 stainless steel manufacturers and suppliers.

Heat Treatment

Annealing and stress-relief improve ductility and corrosion resistance after cold working or welding.

Applications of 201 Stainless Steel – Hanhuang

- Industrial Applications

Used in mechanical components, kitchen equipment, and automotive parts due to its strength, corrosion resistance, and formability. Perfect for B2B manufacturers seeking cost-effective solutions. - Architectural & Decorative Uses

Preferred for architectural elements, furniture, and curtain walls, combining aesthetics and durability. - Food Grade & Hygiene Applications

Suitable for food processing equipment, utensils, and medical instruments, offering hygienic, corrosion-resistant surfaces.

Advantages and Limitations of 201 Stainless Steel – Hanhuang

- Cost-Effective: Lower nickel content reduces material costs for wholesale and factory orders.

- Moderate Corrosion Resistance: Ideal for indoor and light outdoor use.

- Excellent Fabrication: Easy to form, weld, and machine for custom 201 stainless steel projects.

201 Stainless Steel Physical and Mechanical Properties – Hanhuang

| Property | Value | Description |

|---|---|---|

| Density | 7.81 g/cm³ | Standard for austenitic stainless steel, ensuring durability without excessive weight |

| Melting Point | 1400–1450°C | High temperature tolerance for fabrication and processing |

| Thermal Conductivity | 16.2 W/m·K | Moderate heat conduction for machinery components |

| Coefficient of Thermal Expansion | 16.0–17.0 µm/m·°C | Maintains dimensional stability under temperature changes |

| Tensile Strength | 520–750 MPa | Provides robust resistance to stretching under load |

| Yield Strength | 205–275 MPa | Ensures structural integrity under operational stress |

| Hardness | B95 max | Balanced hardness for forming and machining |

| Elongation | ≥40% | High ductility for bending, stamping, and fabrication |

Chemical Properties

Corrosion Resistance: Resists rust in moderate environments; ideal for indoor and light outdoor use.

Oxidation Resistance: Maintains surface finish under normal atmospheric conditions.

Acid & Alkali Resistance: Suitable for food-grade applications and industrial equipment.

201 Stainless Steel Chemical Composition – Hanhuang

| Element | Typical Range | Effect on Performance |

|---|---|---|

| Carbon (C) | 0.07% max | Increases strength, slight impact on corrosion resistance |

| Manganese (Mn) | 5.5–7.5% | Replaces some nickel, improves hardness and tensile strength |

| Nickel (Ni) | 3.5–5.5% | Provides corrosion resistance and enhances ductility |

| Chromium (Cr) | 16–18% | Primary contributor to corrosion resistance |

| Nitrogen (N) | 0.1–0.25% | Strengthens the steel, enhances formability |

Comparison with 304 and 316 Stainless Steel

Cost Advantage: 201 stainless steel contains less nickel than 304/316, reducing material costs.

Performance: Slightly lower corrosion resistance than 304/316, but excellent formability and mechanical strength.

Applications: Ideal for 201 stainless steel suppliers serving industrial, architectural, and commercial sectors.

Related Product

Brushed Stainless Steel

Etched Stainless Steel

Perforated Stainless Steel

Colored Stainless Steel