304 Stainless Steel Solutions

304 Stainless Steel Supplier In China

Hanhuang is a trusted 304 Stainless Steel manufacturer, offering industrial-grade austenitic stainless steel with excellent corrosion resistance, high strength, and durability. Ideal for applications exposed to moisture, chemicals, or high temperatures, our 304 stainless steel is widely used in industrial, commercial, and food-grade environments.

We provide multiple variants, including 304L (low carbon) for improved weldability and 304H (high carbon) for enhanced strength at elevated temperatures, allowing clients to select the optimal grade for food processing equipment, pharmaceutical machinery, architectural components, and transportation applications.

304 Stainless Steel By Shapes

Advantages & Limitations for Industrial Use of 304 Stainless Steel

Advantages:

- Corrosion Resistance: Exceptional rust and oxidation resistance.

- High-Temperature Tolerance: Reliable in heat-intensive operations.

- Processing Flexibility: Excellent weldability, machinability, and formability.

- Extended Service Life: Durable under demanding conditions.

- Cost Efficiency: High performance at reasonable cost.

Limitations:

- Less resistant than 316 stainless steel in high-chloride environments.

- Lower-cost alternatives like 201 stainless steel may be sufficient for non-critical applications.

Industrial Applications of 304 Stainless Steel

304 stainless steel is widely used for its durability and versatility:

- Food Processing & Pharmaceutical Equipment: Mixers, tanks, piping, and processing units.

- Commercial Kitchens & Catering Equipment: Appliances and cookware.

- Architectural & Construction: Facades, curtain walls, and piping systems.

- Transportation & Automotive Components: Vehicle parts and rail components.

Industrial Machinery & Metal Fabrication: Machinery parts and equipment housings.

Chemical Composition of 304 Stainless Steel

304 stainless steel is formulated with carefully balanced alloying elements, each contributing to corrosion resistance, mechanical performance, and processing capability.

| Element | Typical Content (%) | Industrial Function |

|---|---|---|

| Chromium (Cr) | 18–20 | Corrosion resistance, oxidation protection |

| Nickel (Ni) | 8–10.5 | Austenitic structure, toughness, corrosion resistance |

| Carbon (C) | ≤0.08 | Strength and hardness; 304L variant improves weldability |

| Manganese (Mn) | ≤2 | Deoxidizer; improves hot-working performance |

| Silicon (Si) | ≤1 | Strength and oxidation resistance |

| Phosphorus (P) | ≤0.045 | Improves corrosion resistance; minimal impact |

| Sulfur (S) | ≤0.03 | Improves machinability; slightly reduces corrosion resistance |

Selecting the appropriate variant, such as 304L for welding or 304H for high-temperature strength, optimizes performance for industrial projects, reinforcing Hanhuang’s position as a leading 304 Stainless Steel manufacturer.

Related Product

Brushed Stainless Steel

Etched Stainless Steel

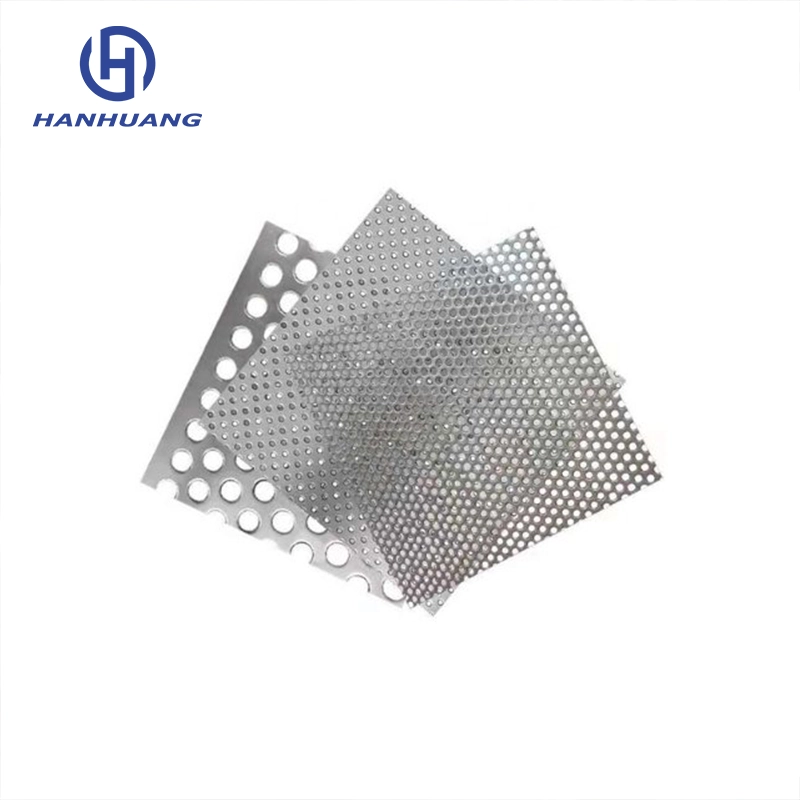

Perforated Stainless Steel

Colored Stainless Steel