309S Stainless Steel Solutions

309S Stainless Steel Manufacturer In China

309S Stainless Steel is an austenitic grade known for its exceptional heat resistance and oxidation resistance. Designed to withstand the demands of high-temperature environments, 309S is commonly used in applications that require outstanding heat expansion and corrosion resistance, such as industrial furnaces, heat exchangers, and combustion chambers.

With its high chromium (22-24%) and nickel (12-15%) content, 309S Stainless Steel provides superior heat resistance, making it a preferred material in industries that operate under extreme thermal stress. Even at elevated temperatures, 309S retains its strength and toughness, ensuring long-lasting performance in high-temperature applications.

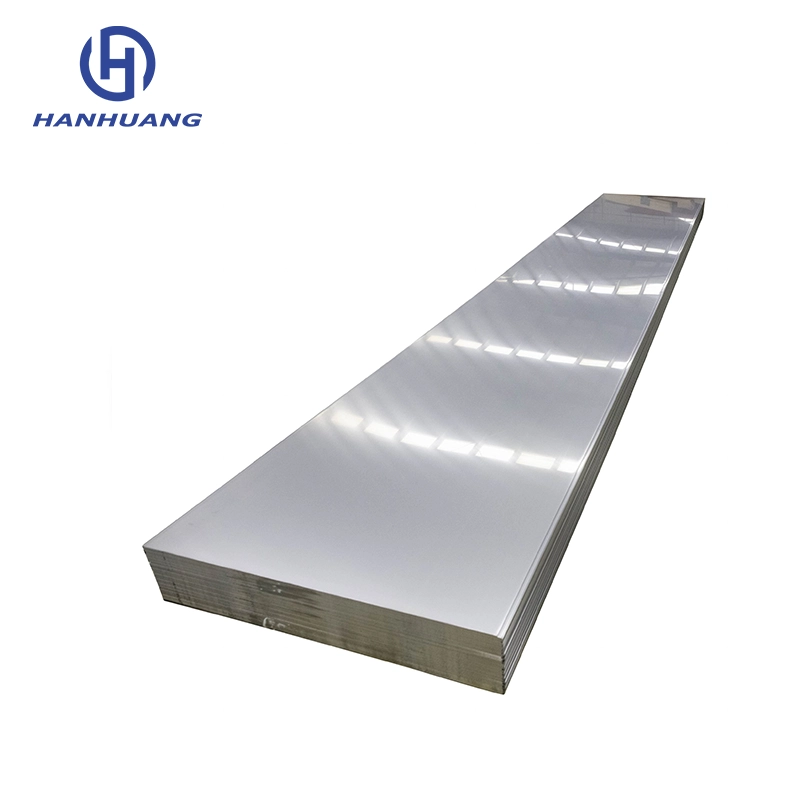

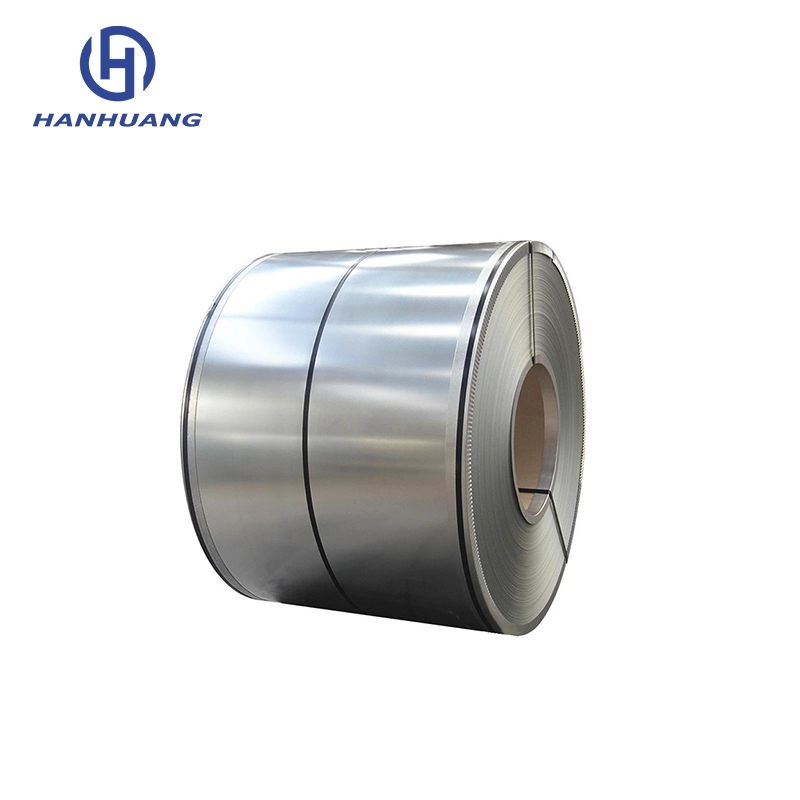

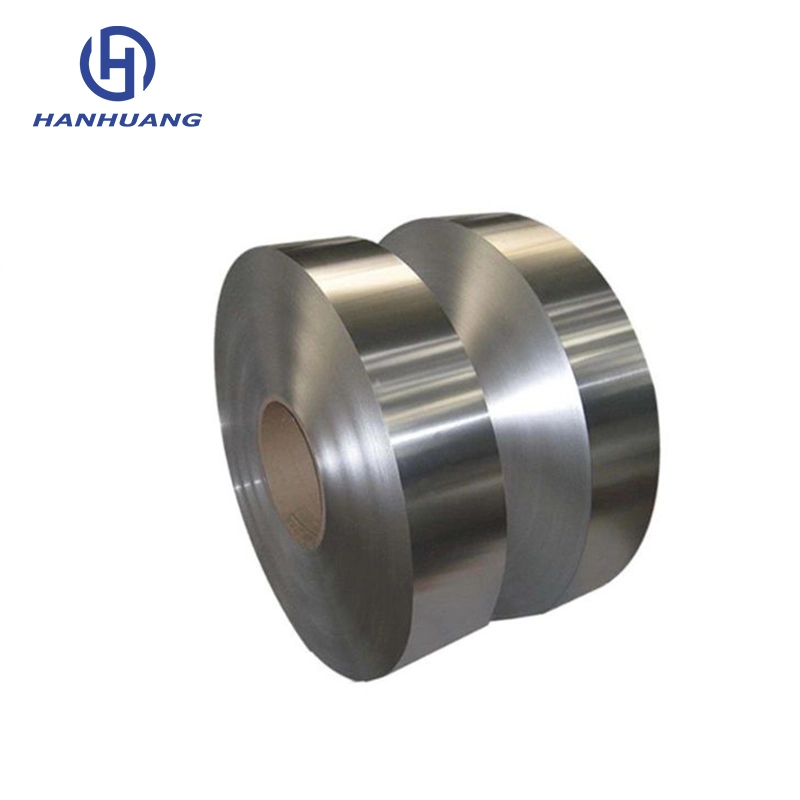

309S Stainless Steel By Shapes

Corrosion Resistance of 309S Stainless Steel

309S Stainless Steel is renowned for its exceptional oxidation resistance, maintaining its structural integrity even in high-temperature environments. It performs especially well in oxidative atmospheres, including high-temperature air and steam, ensuring long-term stability in such challenging conditions.

Its corrosion resistance extends to sulfur-containing environments, making 309S a perfect choice for the chemical and energy industries, where exposure to harsh conditions is common. The superior antioxidant and corrosion-resistant properties of 309S ensure that it can withstand prolonged exposure to high-temperature, corrosive environments without compromising performance.

Why Choose 309S Stainless Steel?

309S Stainless Steel stands out due to its exceptional heat and corrosion resistance, making it ideal for long-term use in high-temperature environments. Its superior oxidation resistance ensures stable performance even under extreme conditions, particularly in applications requiring extended exposure to high heat.

The material’s low carbon content improves its weldability by minimizing carbide precipitation during welding, ensuring a high-quality finish and reducing the risk of weld defects.

Additionally, 309S’s durability in high-temperature, high-stress environments reduces the need for frequent replacements and maintenance, significantly lowering long-term operational costs. When high-performance materials are essential, 309S provides the ideal solution for extreme working conditions that other alloys cannot handle.

309S Stainless Steel Chemical Composition

The chemical composition of 309S Stainless Steel is key to its remarkable performance in high-temperature and corrosive environments. With chromium content ranging from 22-24% and nickel content between 12-15%, 309S excels in oxidation resistance and maintains its integrity under extreme conditions.

The low carbon content (<0.08%) plays a crucial role in minimizing carbide precipitation during welding, significantly improving weldability and reducing the risk of sensitization, which is common in high-temperature applications.

| Element | Percentage |

|---|---|

| Chromium | 17-19% |

| Nickel | 4-6% |

| Manganese | 7-9% |

| Nitrogen | ≤0.25% |

| Carbon | ≤0.08% |

The optimized chemical composition of 309S not only enhances its oxidation and high-temperature strength but also gives it a competitive edge for use in industries like chemicals, energy, and manufacturing. Compared to standard 309 Stainless Steel, the lower carbon content of 309S makes it more stable during welding, ensuring high-quality, reliable performance in demanding environments.

Brushed Stainless Steel

Etched Stainless Steel

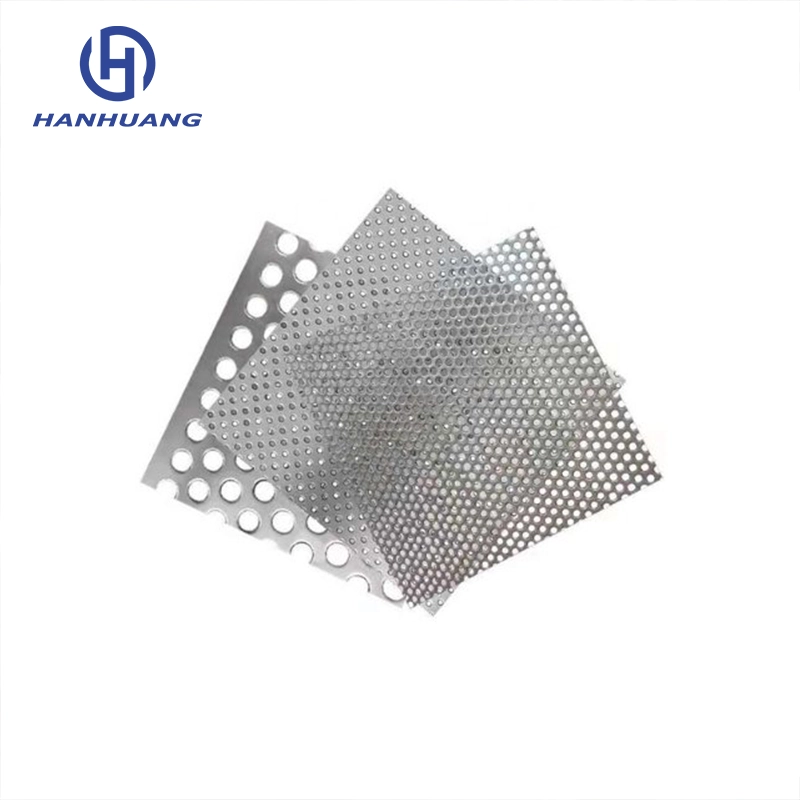

Perforated Stainless Steel

Colored Stainless Steel