310S Stainless Steel Solutions

310S Stainless Steel Manufacturer In China

310S Stainless Steel is a high-performance austenitic steel, known for its excellent resistance to high temperatures and corrosion. The material features high chromium (25%-30%) and nickel (19%-22%) content, ensuring outstanding oxidation resistance in extreme conditions. 310S is widely used in industries such as metallurgy, petrochemicals, and heat exchangers, where durability and performance at high temperatures are critical.

310S Stainless Steel By Shapes

310S Stainless Steel Typical Applications

310S Stainless Steel excels in extreme environments, making it ideal for several industrial applications:

High-Temperature Equipment: Used in furnaces, heat exchangers, and combustion chambers in industries such as metallurgy and petrochemicals.

Chemical Reactors: Its superior corrosion resistance makes it ideal for chemical reactors and piping systems in harsh, high-temperature chemical environments.

Marine Environments: 310S is resistant to seawater corrosion, making it suitable for marine applications such as seawater cooling systems and offshore platforms.

Food Processing: Commonly used in food and dairy processing equipment for its resistance to both high temperatures and corrosion.

310S Stainless Steel Fabrication and Welding

310S Stainless Steel is easy to fabricate and weld, suitable for conventional methods like laser cutting, bending, and stretching. Its low carbon content ensures excellent weldability, with processes such as TIG and MIG welding providing strong, reliable joints without performance degradation.

This makes 310S ideal for applications requiring precision fabrication and high-quality welding.

310S Stainless Steel General Characteristics

310S Stainless Steel boasts excellent resistance to high temperatures and corrosion, especially in chemical reaction environments. Its high chromium and nickel content provide superior oxidation resistance and protection against acidic and alkaline corrosive chemicals.

| Element | Composition (%) | Function |

|---|---|---|

| Chromium (Cr) | 25-30% | Provides excellent heat resistance and oxidation resistance, significantly improving corrosion resistance. |

| Nickel (Ni) | 19-22% | Enhances corrosion resistance, especially at high temperatures, preventing oxidation layer peeling. |

| Carbon (C) | ≤0.08% | Low carbon content reduces carbide precipitation during welding, improving weldability and overall performance. |

| Silicon (Si) | 1.5%-3% | Increases oxidation resistance at high temperatures. |

| Other Elements | Trace amounts of Manganese (Mn), Phosphorus (P), etc. | Enhance the material's overall performance and mechanical properties. |

Related Product

Brushed Stainless Steel

Etched Stainless Steel

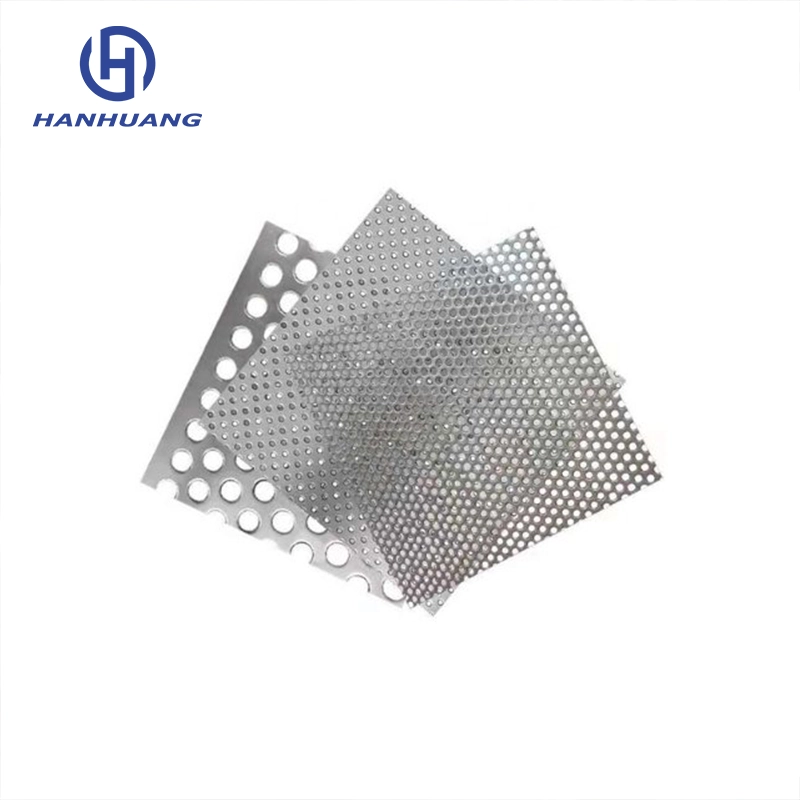

Perforated Stainless Steel

Colored Stainless Steel