317 Stainless Steel Solutions

317 Stainless Steel Manufacturer In China

317 Stainless Steel offers exceptional corrosion resistance and durability, making it ideal for applications in challenging environments. Its high molybdenum content enhances its performance in chloride-rich and high-temperature conditions.

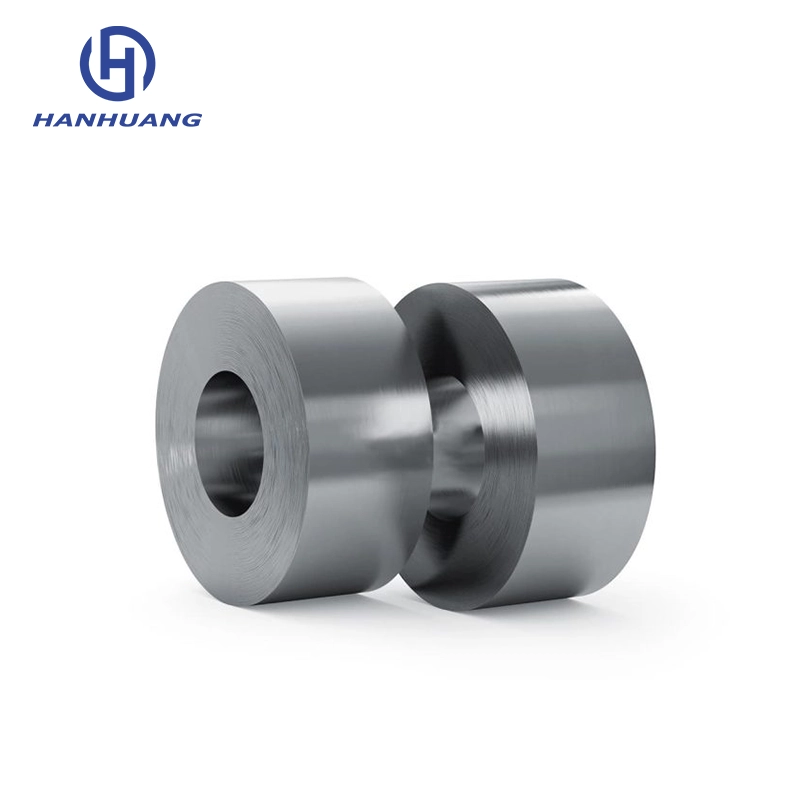

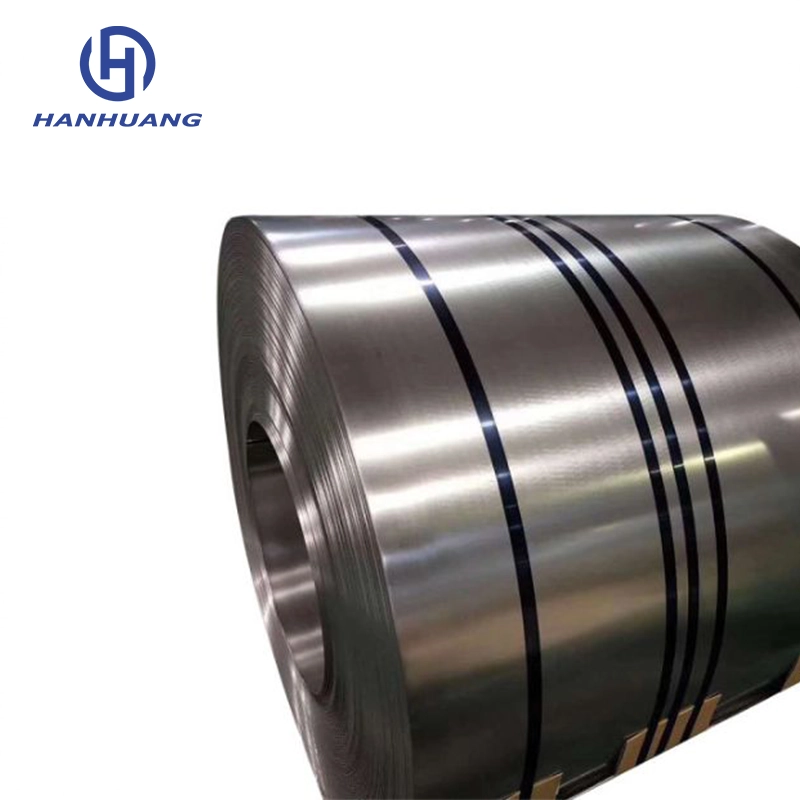

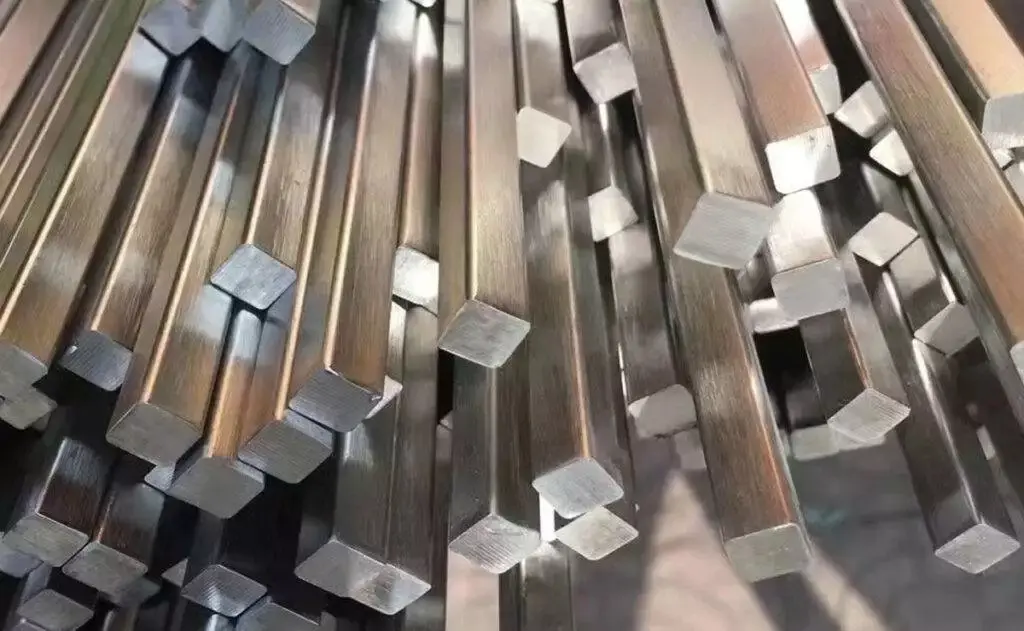

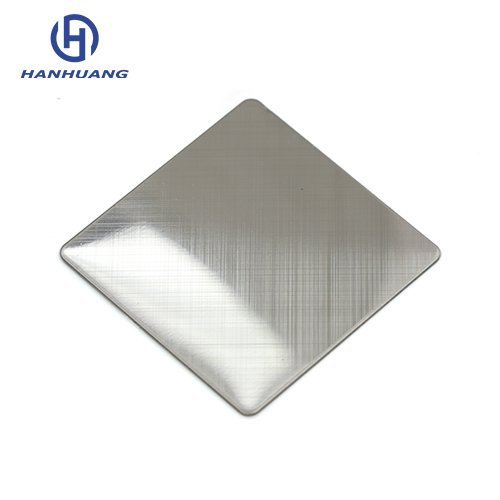

317 Stainless Steel By Shapes

317 Stainless Steel - Common Applications

317 Stainless Steel is widely used across various industries due to its excellent corrosion resistance and high-temperature performance.

Chemical and Petrochemical Industries:

Ideal for reactors, storage tanks, and heat exchangers, 317 Stainless Steel performs exceptionally well in environments with acidic, chloride, and other corrosive elements.

Food and Pharmaceutical Industries:

This alloy is used in food processing equipment and pharmaceutical reactors, meeting strict hygiene and corrosion resistance standards for safe and reliable operations.

Marine and Offshore Platforms:

Known for its outstanding seawater corrosion resistance, 317 Stainless Steel is extensively used in ships, offshore oil platforms, and seawater systems, ensuring durability in harsh marine environments.

317 Stainless Steel - Key Advantages

317 Stainless Steel offers a range of outstanding advantages that make it an ideal choice for demanding applications in harsh environments.

Exceptional Corrosion Resistance:

317 Stainless Steel maintains its integrity in extreme conditions, including chloride-rich and high-temperature environments.

Outstanding High-Temperature Performance:

With the ability to withstand temperatures up to 870°C, 317 Stainless Steel performs excellently in high-temperature oxidation environments, making it suitable for applications like heat exchangers and reactors.

Strength and Toughness:

Compared to 304 and 316 Stainless Steel, 317 offers superior mechanical strength, especially in acidic and high-temperature environments, providing added durability in critical applications.

Long-Term Durability:

317 Stainless Steel boasts a longer lifespan compared to other stainless steels, reducing the need for frequent maintenance or replacement, making it a cost-effective solution for industries requiring high reliability.

317 Stainless Steel - Chemical Composition

The chemical composition of 317 Stainless Steel is what gives it exceptional performance in corrosive and high-temperature environments. The key alloying elements, including chromium, nickel, and molybdenum, work together to provide outstanding corrosion resistance, high-temperature durability, and mechanical strength.

Chromium (Cr): Enhances corrosion resistance, particularly in oxidative environments, preventing rust formation.

Nickel (Ni): Increases the material’s resistance to corrosion and improves toughness, ensuring stability in extreme environments.

Molybdenum (Mo): Molybdenum is a significant element in 317 Stainless Steel, improving its resistance to chlorides and sulfides, particularly in acidic environments and marine applications.

Other trace elements: Silicon (Si), Manganese (Mn), and Nitrogen (N) help optimize physical and mechanical properties, ensuring the steel’s stability in various industrial applications.

| Element | Content Range (%) | Key Function |

|---|---|---|

| Chromium (Cr) | 17-20 | Enhances corrosion resistance, oxidation resistance |

| Nickel (Ni) | 11-15 | Increases corrosion resistance, improves toughness |

| Molybdenum (Mo) | 2.5-3.0 | Improves resistance to chlorides, sulfides |

| Silicon (Si) | ≤1.0 | Increases heat resistance, enhances oxidation resistance |

| Manganese (Mn) | ≤2.0 | Enhances strength and hardness |

| Nitrogen (N) | ≤0.1 | Increases strength, enhances corrosion resistance |

Related Product

Brushed Stainless Steel

Etched Stainless Steel

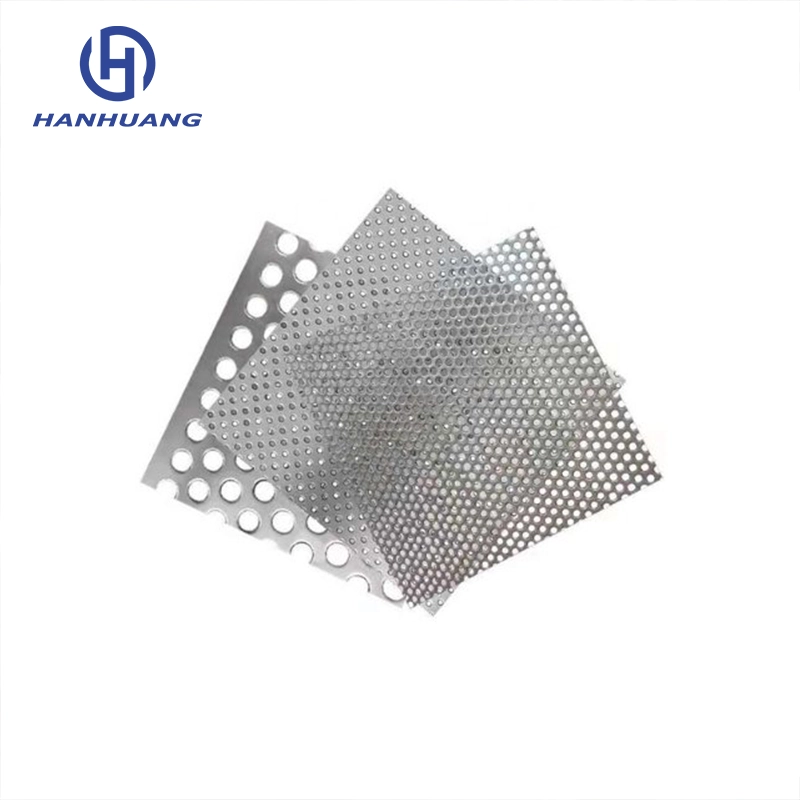

Perforated Stainless Steel

Colored Stainless Steel