317L Stainless Steel Solutions

317L Stainless Steel Manufacturer In China

317L Stainless Steel is a high-performance alloy designed for superior corrosion resistance and high-temperature performance. Composed of a high percentage of chromium, nickel, and molybdenum, 317L Stainless Steel offers excellent resistance to chloride-induced pitting and crevice corrosion, making it ideal for aggressive environments. Unlike standard alloys like 304L and 316L, 317L has a low carbon content, which helps minimize intergranular corrosion, particularly in welded areas.

Key advantages of 317L Stainless Steel over other alloys include its superior resistance to sulfuric and phosphoric acids, along with its ability to withstand high temperatures up to 900°C. This makes it an ideal choice for applications in chemical processing, marine, and aerospace industries.

317L Stainless Steel is widely used in industries such as chemical processing, marine engineering, and food production, offering unmatched reliability and durability in harsh, corrosive environments.

317L Stainless Steel By Shapes

Advantages of 317L Stainless Steel

Superior Corrosion Resistance

317L Stainless Steel excels in harsh chemical and marine environments, offering outstanding protection against pitting, crevice corrosion, and chloride-induced attacks, making it ideal for aggressive conditions.

High-Temperature Stability

Designed to perform in high-temperature applications, 317L maintains its mechanical properties up to 900°C, ensuring reliable operation in extreme heat.

Excellent Weldability

With its low carbon content, 317L boasts excellent weldability, reducing the risk of welding defects and ensuring strong, durable joints.

Long-Term Durability

Compared to other stainless steels, 317L offers a longer lifespan in demanding environments, providing superior performance in applications requiring durability and reliability.

Applications of 317L Stainless Steel

Chemical Processing

317L Stainless Steel is commonly used in chemical reactors, tanks, and piping systems due to its excellent resistance to corrosive chemicals. Its durability ensures long-term performance in harsh environments.

Marine Environments

With its outstanding resistance to saltwater corrosion, 317L is ideal for use in offshore platforms, ships, and other marine structures, ensuring longevity in corrosive seawater conditions.

Food and Beverage

Meeting FDA standards, 317L Stainless Steel is perfect for food-grade equipment, ensuring hygiene and compliance in the food and beverage industry.

Aerospace

The alloy’s high-temperature resistance makes it suitable for aerospace components exposed to extreme conditions.

Power Generation

317L is used in boilers, heat exchangers, and other high-temperature equipment, offering reliable performance under demanding conditions.

Chemical Composition of 317L

| Element | Percentage |

|---|---|

| Chromium (Cr) | 18-20% |

| Nickel (Ni) | 11-14% |

| Molybdenum (Mo) | 3-4% |

| Carbon (C) | ≤0.03% |

| Manganese (Mn) | 2% |

| Silicon (Si) | 1% |

| Phosphorus (P) | ≤0.045% |

| Sulfur (S) | ≤0.03% |

317L Stainless Steel is carefully engineered for optimal performance in aggressive environments. The high levels of chromium, nickel, and molybdenum provide exceptional resistance to corrosion, especially in chloride and acidic environments. The addition of molybdenum (3-4%) enhances its ability to withstand pitting and crevice corrosion, making it suitable for harsh marine and chemical applications.

The low carbon content (≤0.03%) of 317L plays a crucial role in improving its weldability and preventing carbide precipitation during welding. This helps maintain the alloy’s integrity in high-temperature applications, making it more reliable and durable compared to other stainless steels like 316L. This combination of chemical elements ensures 317L Stainless Steel performs exceptionally well in industries that require both high strength and excellent corrosion resistance.

Related Product

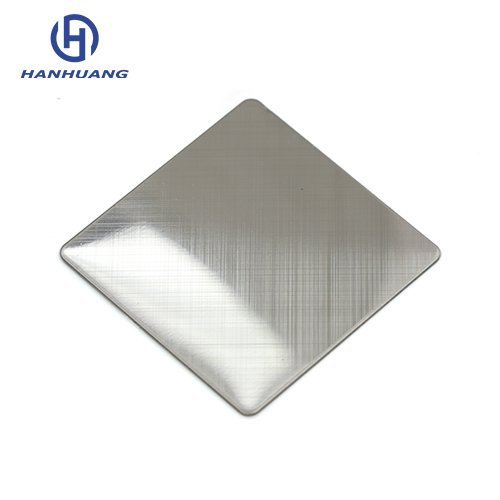

Brushed Stainless Steel

Etched Stainless Steel

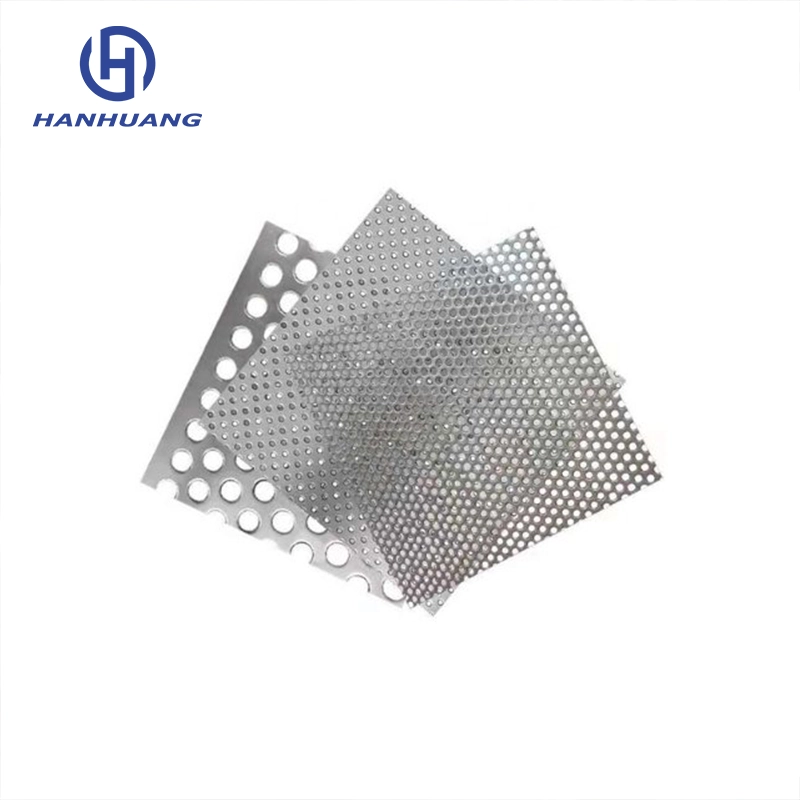

Perforated Stainless Steel

Colored Stainless Steel