347 Stainless Steel Solutions

347 Stainless Steel Manufacturer In China

347 Stainless Steel is a high-performance alloy known for its exceptional resistance to high temperatures and corrosion. Unlike 304 and 316 stainless steels, it offers enhanced stability in extreme heat environments, making it ideal for applications requiring high thermal resistance.

This alloy is widely used in industries such as aerospace, chemical processing, and pharmaceuticals. Typical applications include gas turbines, heat exchangers, and reactor components, where both strength and thermal stability are critical.

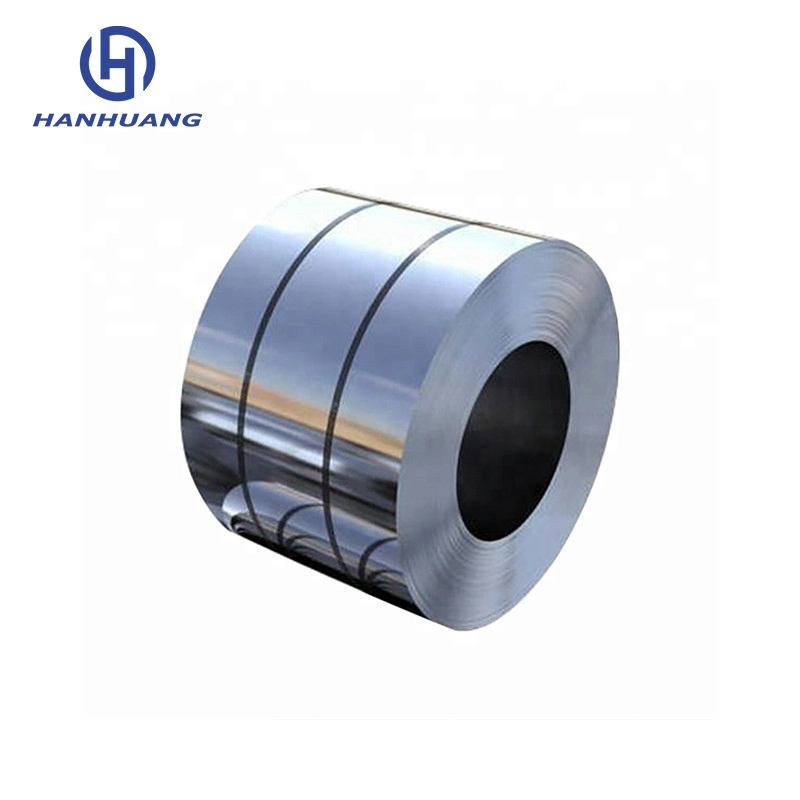

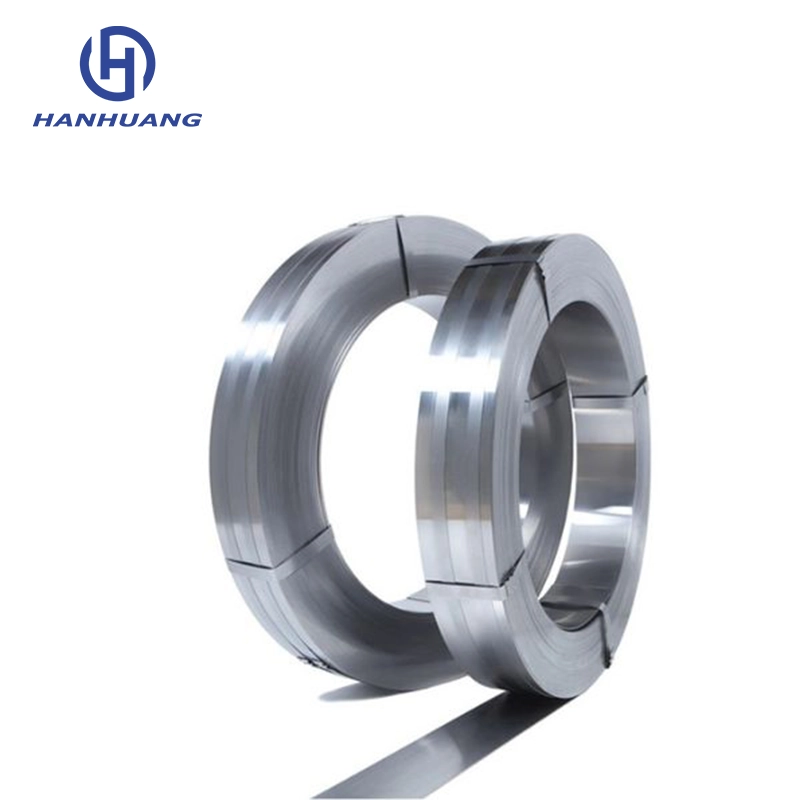

347 Stainless Steel By Shapes

Finishing and Processing Options

Standard Finishes

Common surface finishes for 347 Stainless Steel include brushed, mirror, and bright annealed. These finishes enhance the material’s aesthetic appeal and provide added protection against corrosion. Brushed finishes are ideal for reducing friction, while mirror and bright annealed finishes improve the material’s resistance to oxidation.

Cold Forming and Tempering

Cold forming enhances the mechanical properties of 347 Stainless Steel, particularly in terms of tensile strength and wear resistance. Tempering, typically performed after cold forming, further improves the steel’s hardness and toughness, making it more suitable for high-stress applications.

Edge Conditioning and Slitting

Edge conditioning and slitting are key processes that ensure clean, sharp edges and optimal product performance. These methods are particularly important in applications requiring precise fits and clean installations, minimizing the risk of damage during assembly or operation.

Applications of 347 Stainless Steel

Industries & Uses

347 Stainless Steel is commonly used in industries requiring high-temperature performance and corrosion resistance. Key industries include aerospace, chemical processing, and energy. It is ideal for environments that demand stability under extreme heat, such as aerospace engines, chemical reactors, and oil & gas pipelines.

Specific Components

347 Stainless Steel is often used to manufacture critical components such as gas turbine blades, furnace parts, and reactor chambers. Its ability to maintain strength and resistance to oxidation at elevated temperatures makes it indispensable in these high-stress applications.

General Properties of 347 Stainless Steel

| Property | Details |

|---|---|

| Chemical Composition | 347 Stainless Steel primarily contains 17-19% chromium, 9-13% nickel, and small amounts of niobium. Chromium enhances corrosion resistance, nickel improves toughness, and niobium stabilizes the material against high-temperature sensitization. |

| Physical Properties | Density: 8.00 g/cm³, Melting Point: 1400-1450°C, Thermal Conductivity: 16.3 W/m·K. These properties ensure 347 maintains strength and stability even at elevated temperatures. |

| Mechanical Properties | Tensile Strength: 515-755 MPa, Yield Strength: 205-290 MPa, Hardness: Rockwell B 85-95. Conforms to ASTM A240 for consistent quality and performance. |

| Corrosion Resistance | Exceptional resistance to oxidation and corrosion, especially in high-temperature and acidic environments. Resists sulfuric and phosphoric acids as well as high-temperature oxidation. |

| Heat Treatment | Annealing and solution treatment at 1010-1120°C improves strength and corrosion resistance. Proper heat treatment helps in achieving desired mechanical properties. |

| Weldability | 347 Stainless Steel can be welded using TIG and MIG methods. Post-welding heat treatment is recommended to reduce stresses and improve material properties. |

Related Product

Brushed Stainless Steel

Etched Stainless Steel

Perforated Stainless Steel

Colored Stainless Steel