410 Stainless Steel Solutions

410 Stainless Steel Manufacturer In China

410 Stainless Steel, also known as UNS S41000, is a high-carbon, martensitic stainless steel that combines excellent hardness and strength. As part of the 400 series, this steel offers great durability and wear resistance, making it ideal for demanding applications.

Its unique properties make 410 Stainless Steel perfect for use in environments requiring both high strength and moderate corrosion resistance. It performs well in high-temperature settings and can withstand light corrosive conditions.

Commonly used in industries such as manufacturing, automotive, and aerospace, 410 Stainless Steel is particularly suitable for components like valves, shafts, and other heavy-duty parts where durability and wear resistance are essential.

410 Stainless Steel By Shapes

410 Stainless Steel Corrosion Resistance

410 Stainless Steel offers good corrosion resistance in low to moderate corrosive environments. While it is not as resistant to corrosion as grades like 304 or 316, it performs well in less aggressive conditions, such as those found in the petroleum, automotive, and general industrial sectors.

Unlike 304 and 316 stainless steels, which have higher nickel content for better corrosion resistance, 410 Stainless Steel’s relatively low chromium content limits its resistance to harsh corrosive environments. However, it remains highly effective in environments with mild corrosion, making it a cost-effective choice for applications where high resistance is not essential.

410 Stainless Steel is ideal for use in industries where durability and moderate corrosion resistance are required, without the higher cost of other stainless steel grades.

Heat Resistance & Heat Treatment of 410 Stainless Steel

410 Stainless Steel offers excellent heat resistance, making it suitable for applications in high-temperature environments. Its ability to maintain strength and hardness at elevated temperatures ensures reliable performance in industries like automotive and manufacturing.

To further enhance its properties, 410 Stainless Steel can undergo heat treatments such as tempering and annealing. These processes improve its hardness and strength while also increasing its resistance to oxidation. Tempering, in particular, helps relieve internal stresses, enhancing the steel’s toughness and durability in extreme conditions.

By optimizing these heat treatment processes, 410 Stainless Steel becomes even more resistant to wear, making it an excellent choice for heavy-duty components that must withstand high temperatures.

410 Stainless Steel Chemical Composition

The chemical composition of 410 Stainless Steel plays a crucial role in its performance, providing a balance of strength, corrosion resistance, and wear resistance. Below is the breakdown of the key elements found in 410 Stainless Steel:

| Element | Percentage |

|---|---|

| Chromium (Cr) | 16-18% |

| Carbon (C) | Max. 0.15% |

| Manganese (Mn) | 1.0% Max |

| Nickel (Ni) | 0.75% Max |

| Silicon (Si) | 1.0% Max |

These alloying elements give 410 Stainless Steel its robust hardness and strength, along with moderate corrosion resistance. The high chromium content improves wear resistance and oxidation at elevated temperatures, while the low carbon level ensures good machinability. Together, these elements make 410 Stainless Steel a suitable choice for high-stress, high-temperature, and mildly corrosive environments.

Related Product

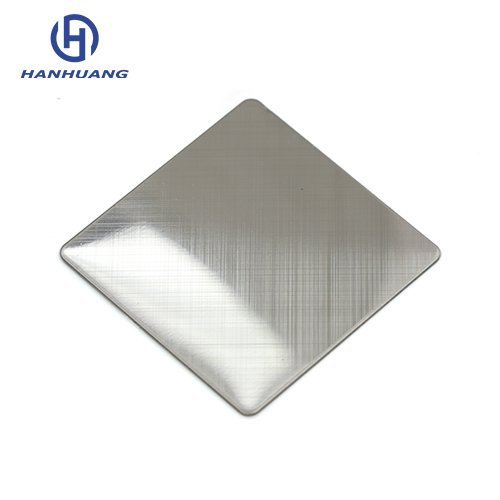

Brushed Stainless Steel

Etched Stainless Steel

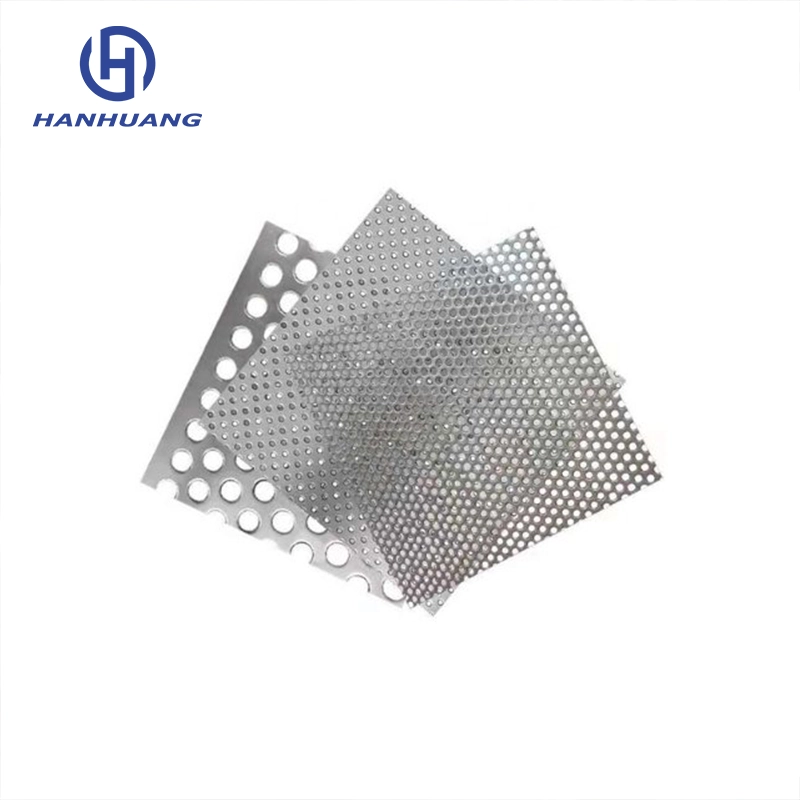

Perforated Stainless Steel

Colored Stainless Steel