420J1 Stainless Steel Solutions

420J1 Stainless Steel Manufacturer In China

420J1 Stainless Steel is a martensitic stainless steel known for its excellent hardness and wear resistance, making it a popular choice in tool manufacturing and other high-strength applications. Its high-carbon content enhances its hardness, providing greater durability in demanding environments, especially where wear and tear are a concern.

This steel type is ideal for products that require high-strength performance, such as cutting tools, surgical instruments, and automotive parts. Its excellent wear resistance makes it suitable for applications subjected to significant mechanical stress.

420J1 Stainless Steel By Shapes

Mechanical Properties of 420J1 Stainless Steel

420J1 Stainless Steel is known for its impressive mechanical properties:

Tensile Strength: It has a high tensile strength, making it capable of withstanding significant pulling forces.

Hardness: The steel exhibits a very high hardness (Rockwell hardness HRC 50-55), making it ideal for wear-resistant applications.

Yield Strength: The yield strength of 420J1 is relatively high, allowing it to endure significant pressure and physical impact without permanent deformation.

These properties make 420J1 a popular choice for high-stress, high-durability applications where both strength and wear resistance are essential.

Physical Properties of 420J1 Stainless Steel

420J1 Stainless Steel has the following physical properties:

Density & Weight: The typical density of 420J1 is 7.75-7.80 g/cm³, making it suitable for applications where weight is a consideration.

Corrosion Resistance: It provides good corrosion resistance in neutral or mildly acidic environments, making it ideal for medical devices and automotive parts.

High-Temperature Performance: While 420J1 performs well at high temperatures, its heat resistance is slightly lower than that of 420J2. However, it remains stable in moderate high-temperature environments.

These characteristics make 420J1 versatile for a wide range of applications requiring strength, corrosion resistance, and stability under varying conditions.

Chemical Composition of 420J1 Stainless Steel

420J1 Stainless Steel consists of approximately 0.15-0.40% carbon and 12-14% chromium. This combination of elements enhances its hardness and wear resistance while providing good corrosion resistance, particularly in neutral or mildly acidic environments.

The high chromium content improves its ability to resist oxidation and corrosion, while the carbon content contributes to its high hardness, making it suitable for manufacturing cutting tools, surgical instruments, and other components that require resistance to abrasion.

Related Product

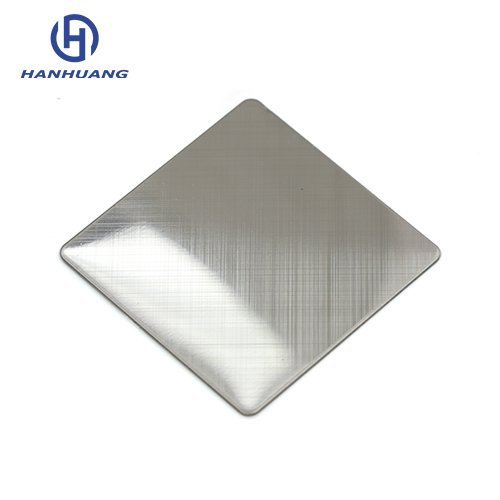

Brushed Stainless Steel

Etched Stainless Steel

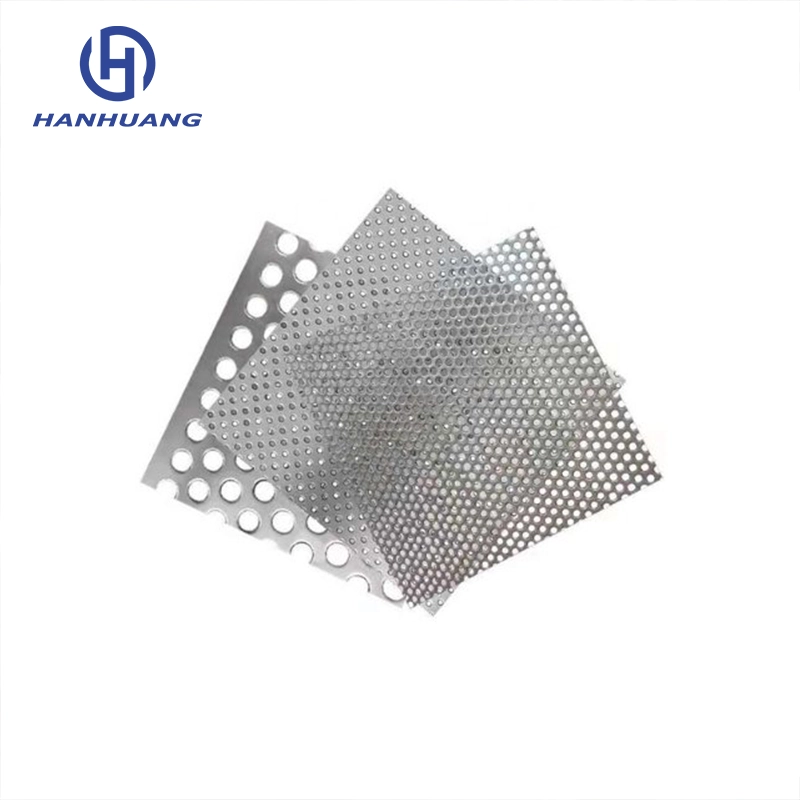

Perforated Stainless Steel

Colored Stainless Steel