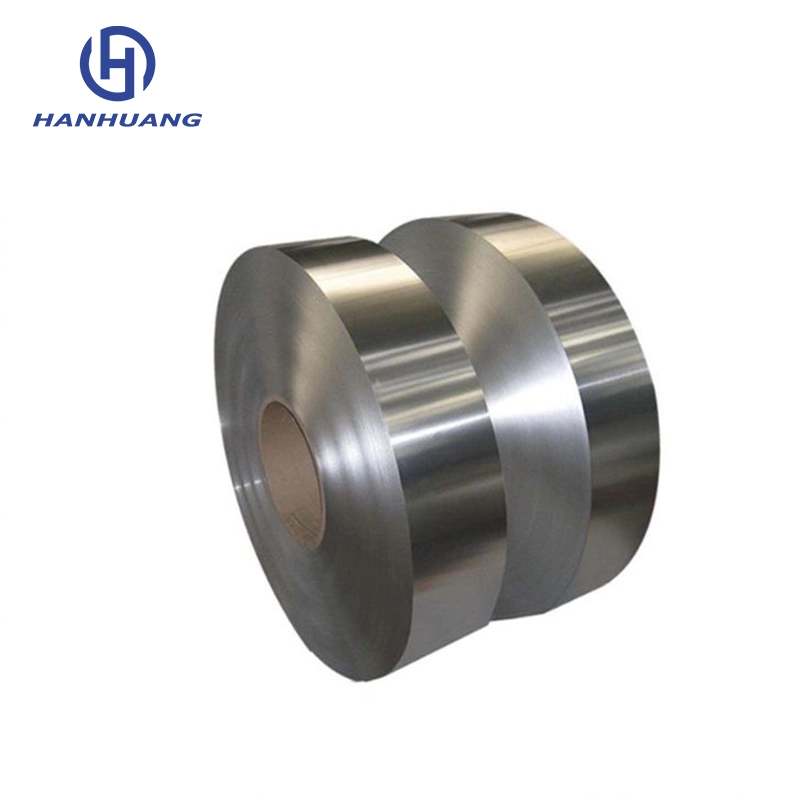

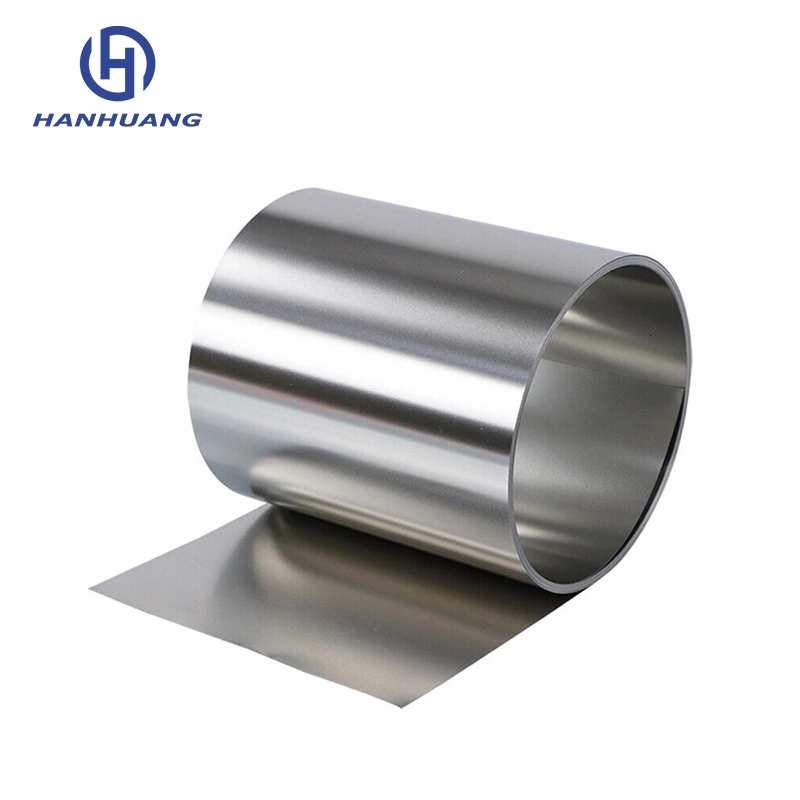

Stainless Steel Strip

Stainless Steel Strip Supplier In China

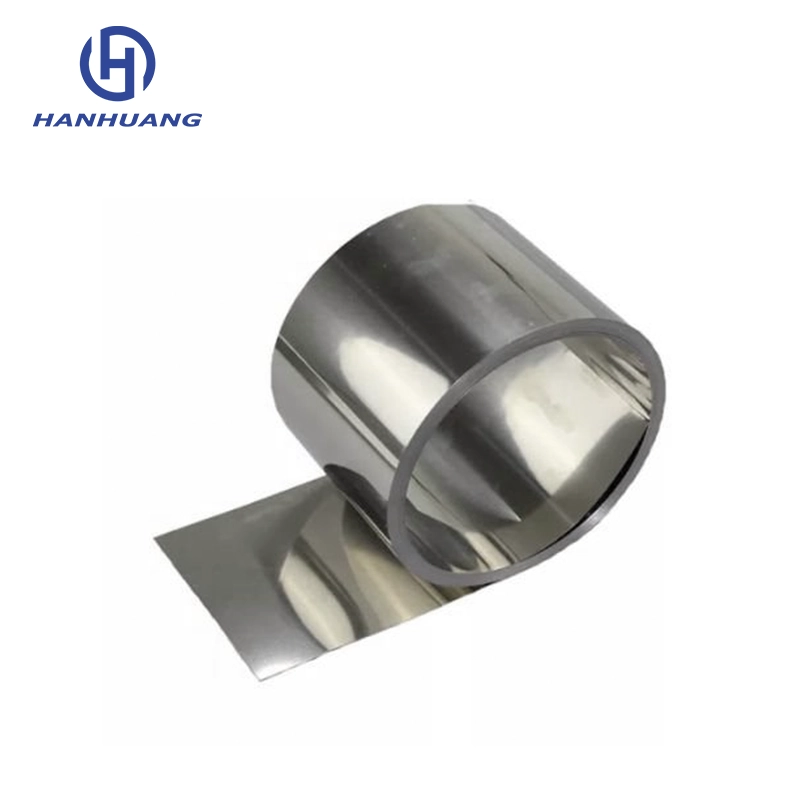

Stainless steel strips are high-quality materials designed for long-lasting performance. The stainless steel surface ensures resistance to corrosion, chemicals, and physical wear, making them ideal for industrial, outdoor, and high-demand environments.

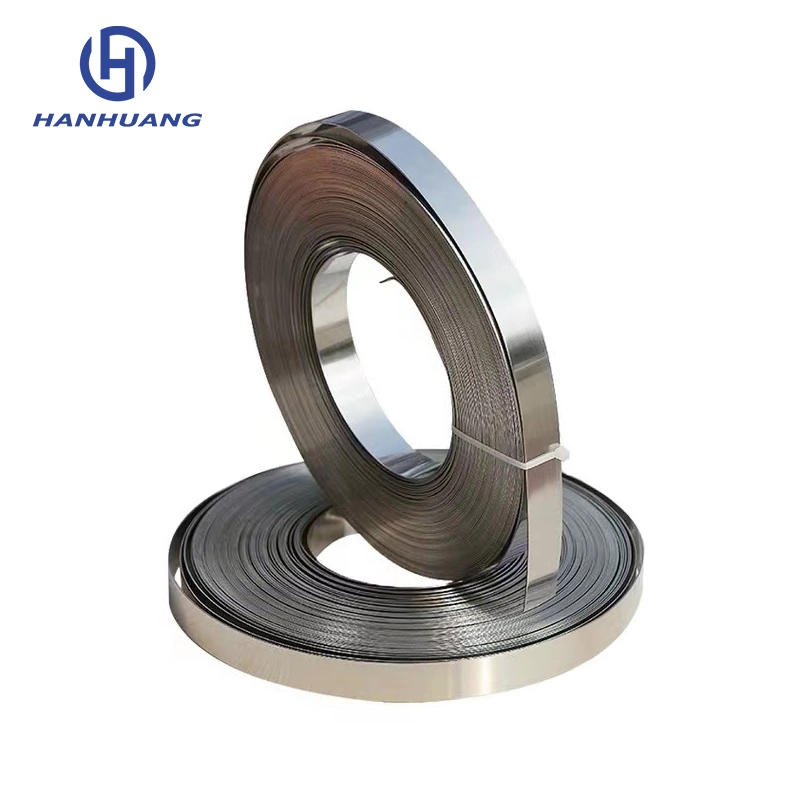

Hanhuang stainless steel strips are available in various widths, thicknesses, and lengths and can be customized to meet exact project specifications. Our wholesale stainless steel strips are suitable for bulk orders, while our custom fabrication services include cutting, polishing, bending, and shaping.

Perfect for machinery, electrical systems, pipelines, and structural applications, Hanhuang strips offer flexibility, reliability, and cost-effective solutions for B2B clients worldwide.

| Product Parameters: Hanhuang Stainless Steel strip | |||

|---|---|---|---|

| Width | 3mm~2500mm | ||

| Thickness | 0.01mm~20mm | ||

| Standard | ASTM/ASME 240/480,JIS 4305,DIN EN 10088-2 | ||

| Surface | 2B,BA,8K,NO.1,NO.4,NO.3,hairline,gold ,black ,rose gold,etc | ||

| Grades | 201, 202, 301, 304, 304L, 304H, 304DQ, 316, 316L, 316Ti, 317L, 309S, 310S, 321, 347, 347H, 410, 410S, 420, 420J2, 430, 430L, 430J1, 434, 436L, 439, 441, 443, 444, 904L, 2205, 2507, S32750, S32760, 445J2, 442, etc.c | ||

Stainless Steel Strip By Grades

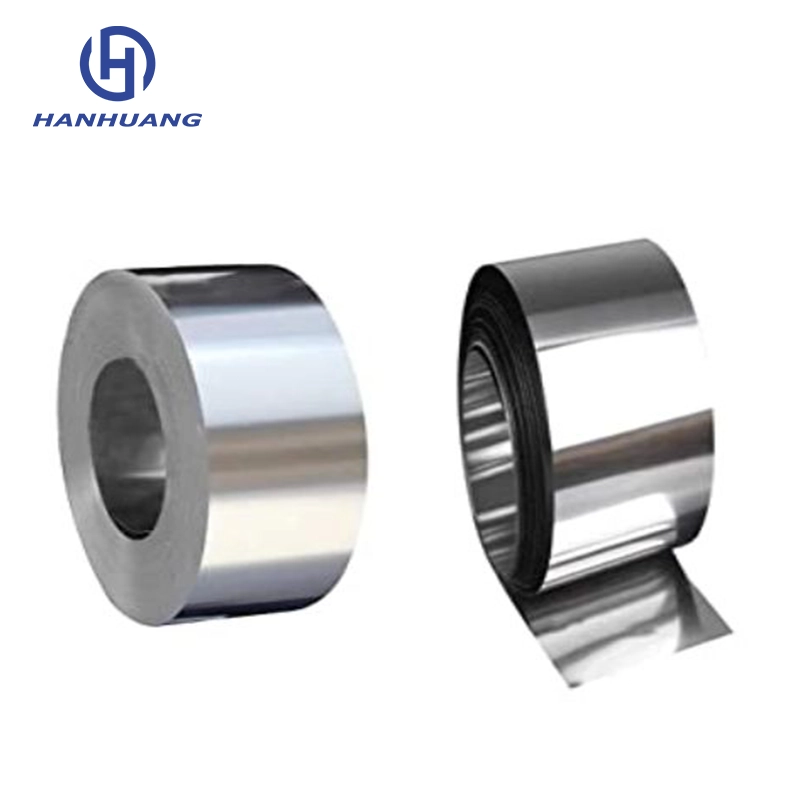

Stainless Steel Strip By Surface Finish

Stainless Steel Strip:Durability

Hanhuang stainless steel strips are engineered for long-term industrial performance, offering exceptional corrosion resistance, mechanical strength, and temperature endurance. Suitable for indoor and outdoor applications, our strips can withstand harsh chemicals, moisture, and heavy-duty wear.

Customizable in widths, thicknesses, surface finishes, and fabrication options, Hanhuang stainless steel strips are suitable for industrial, commercial, and high-precision applications. Post-fabrication treatments like passivation or polishing are recommended for enhanced corrosion resistance.

Stainless Steel Strip Applications

Hanhuang stainless steel strips serve a wide range of applications:

- Construction & Infrastructure– Frameworks, reinforcement, architectural panels, and facade applications.

- Automotive & Machinery Manufacturing– Structural supports, precision components, springs, and safety elements.

- Food & Pharmaceutical Industries– Food-grade stainless steel strips maintaining hygiene, corrosion resistance, and regulatory compliance.

- Industrial & Outdoor Installations– Pipelines, HVAC systems, renewable energy structures, and marine environments requiring high corrosion resistance.

Versatile, durable, and reliable, Hanhuang stainless steel strips provide material solutions for multiple industries, making them an excellent choice for industrial manufacturers, suppliers, and wholesale buyers.

Benefits of Hanhuang Stainless Steel Strips

- Cost-Effective– Long-lasting, low-maintenance solution for industrial and B2B projects.

- High Strength and Durability– Withstands extreme temperatures, heavy loads, and continuous use.

- Corrosion and Chemical Resistance– Ideal for harsh industrial and outdoor conditions.

- Precision and Protection– Shields machinery and components from wear and environmental hazards.

- Environmentally Sustainable– Recyclable, reusable, lightweight, and easy to handle.

- Fire and Heat Resistance– Suitable for high-temperature and chemically exposed environments.

What is stainless steel strip?

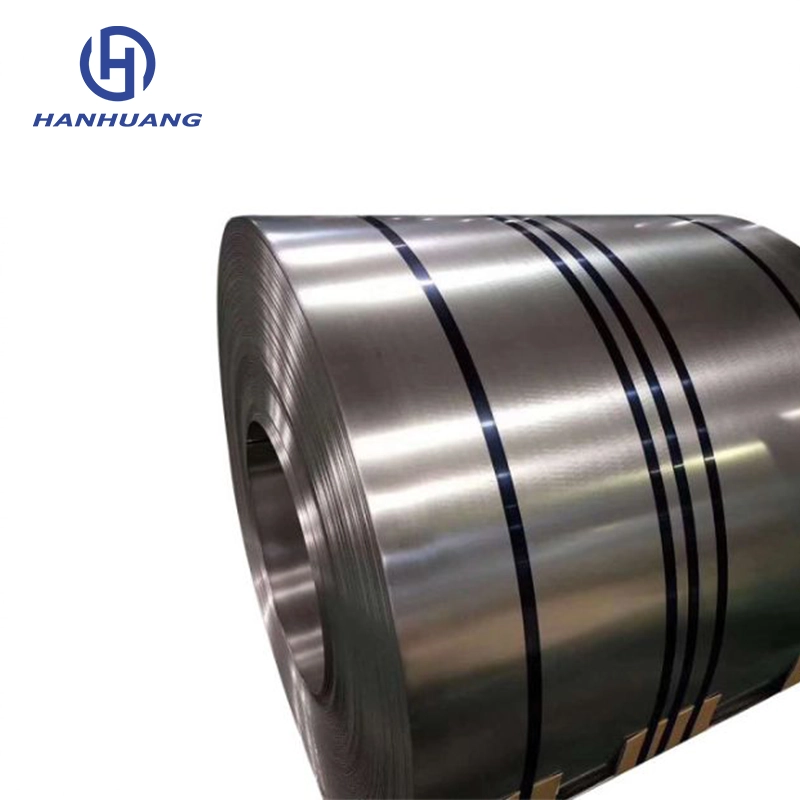

Stainless steel strip is a narrow, flat-rolled product made by slitting wider stainless steel coils into specific widths. It is widely used for springs, tubes, fasteners, and precision components in various industries.

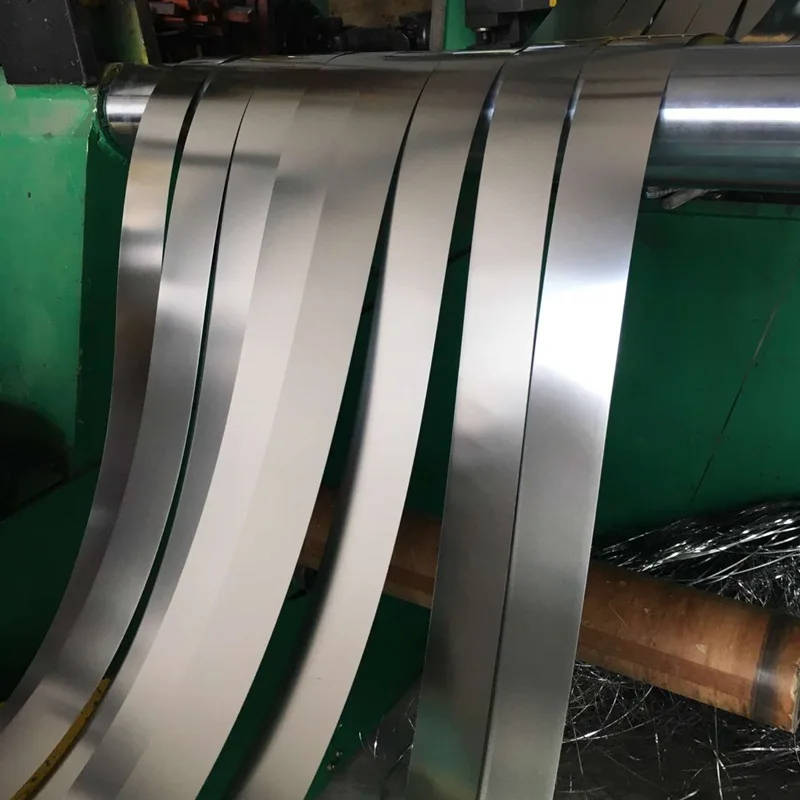

How is stainless steel strip produced?

The production process includes cold rolling, annealing, pickling, and slitting. The wide coil is slit into narrow strips using precision blades, then recoiled for easy transport and further fabrication.

Can stainless steel strip be customized?

Yes. Hanhuang provides custom widths, thicknesses, finishes, and edge types to meet specific production and design requirements.

Ultimate FAQ Guide to Stainless Steel Strips

Chemical and Mechanical Properties of Stainless Steel Strip

Chemical Composition

The chemical composition of stainless steel strip depends on the specific grade, but all contain a combination of iron (Fe), chromium (Cr), nickel (Ni), and other alloying elements that provide corrosion resistance and mechanical strength.

| Grade | Cr (%) | Ni (%) | C (%) | Mn (%) | Si (%) | Mo (%) | N (%) | Typical Features |

|---|---|---|---|---|---|---|---|---|

| 201 | 16–18 | 3.5–5.5 | ≤0.15 | 5.5–7.5 | ≤1.0 | — | — | High strength, cost-effective |

| 304 | 18–20 | 8–10.5 | ≤0.08 | ≤2.0 | ≤1.0 | — | — | Excellent corrosion resistance, most common grade |

| 316L | 16–18 | 10–14 | ≤0.03 | ≤2.0 | ≤1.0 | 2–3 | — | Superior corrosion resistance, marine-grade |

| 430 | 16–18 | — | ≤0.12 | ≤1.0 | ≤1.0 | — | — | Magnetic, good formability, economical |

| 420 | 12–14 | — | 0.15–0.40 | ≤1.0 | ≤1.0 | — | — | High hardness, wear-resistant |

Mechanical Properties

Mechanical properties may vary depending on the grade and processing condition (annealed, hardened, or cold-rolled).

| Property | Typical Range | Description |

|---|---|---|

| Tensile Strength | 520–1,200 MPa | Indicates resistance to breaking under tension |

| Yield Strength | 200–600 MPa | Stress at which permanent deformation begins |

| Elongation | 30–55% | Measures ductility and formability |

| Hardness (HRB) | 70–100 | Depends on grade and heat treatment |

| Density | 7.9 g/cm³ (average) | Varies slightly by composition |