321 Stainless Steel Solutions

321 Stainless Steel Manufacturer In China

321 Stainless Steel is designed for exceptional performance in high-temperature and corrosive environments. It combines chromium, nickel, and titanium for enhanced oxidation resistance, making it ideal for applications in the aerospace, chemical, and power generation industries.

This alloy excels in environments exposed to high-temperature gases, acids, and salts. It is commonly used in exhaust systems, heat exchangers, and manifolds, where superior corrosion resistance and long-term durability are essential.

321 Stainless Steel By Shapes

Physical Properties of 321 Stainless Steel

The key physical properties of 321 Stainless Steel include:

Density: 7.90 g/cm³

Thermal Conductivity: 16.2 W/m·K

Electrical Resistivity: 0.72 µΩ·cm

Melting Point: 1400 – 1450°C

Regarding magnetic properties, 321 Stainless Steel is generally non-magnetic, with only minimal magnetic permeability under certain conditions. This makes it suitable for applications where magnetism could be a concern.

Corrosion Resistance of 321 Stainless Steel

321 Stainless Steel offers excellent resistance to corrosion in acidic, sulfuric, and saline environments. It withstands exposure to harsh chemicals, acids, and saltwater, making it ideal for chemical, marine, and industrial applications.

At high temperatures, its oxidation resistance is also superior, preventing the material from deteriorating in environments with elevated heat and aggressive gases. This makes it highly suitable for use in energy, chemical, and other high-corrosion industries.

Chemical Composition of 321 Stainless Steel

| Element | Composition (%) |

|---|---|

| Chromium (Cr) | 17.0 - 19.0 |

| Nickel (Ni) | 9.0 - 12.0 |

| Titanium (Ti) | 5x(C - 0.08) |

| Manganese (Mn) | 2.0 max |

| Carbon (C) | 0.08 max |

| Iron (Fe) | Balance |

The typical chemical composition of 321 Stainless Steel includes:

Titanium (Ti) plays a key role in enhancing the alloy’s stability and oxidation resistance. It forms titanium carbides, which prevent the formation of chromium carbides, ensuring that the material retains its corrosion resistance and structural integrity, even at elevated temperatures.

Related Product

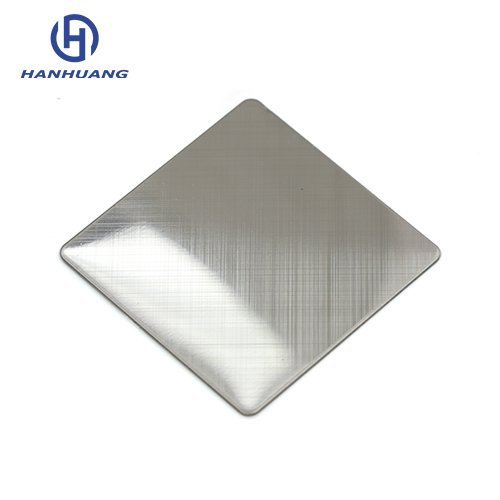

Brushed Stainless Steel

Etched Stainless Steel

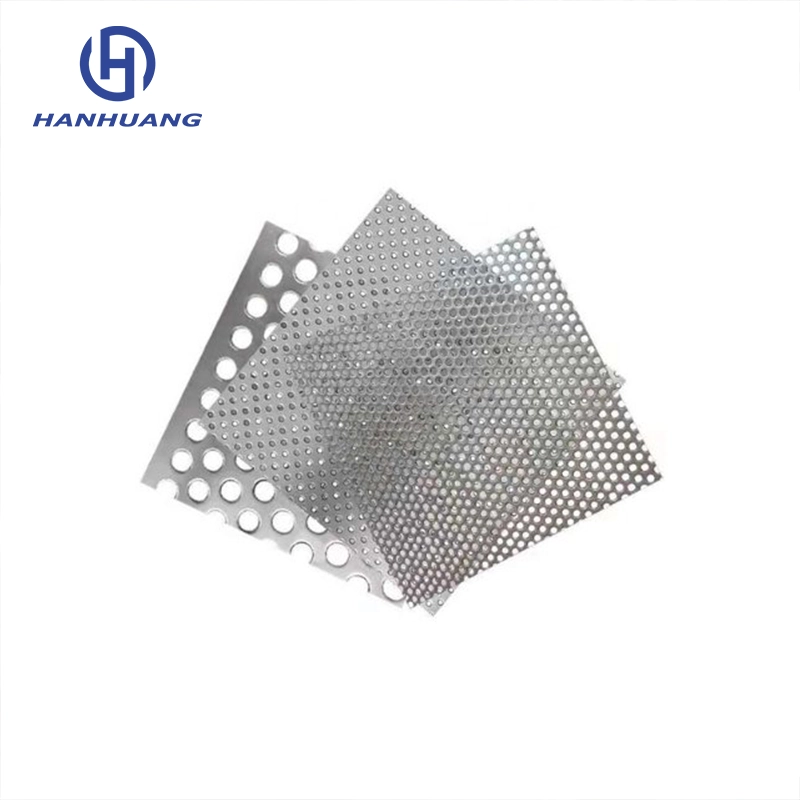

Perforated Stainless Steel

Colored Stainless Steel