Product Feature

201 stainless steel offers diverse options to fit different industries and applications:

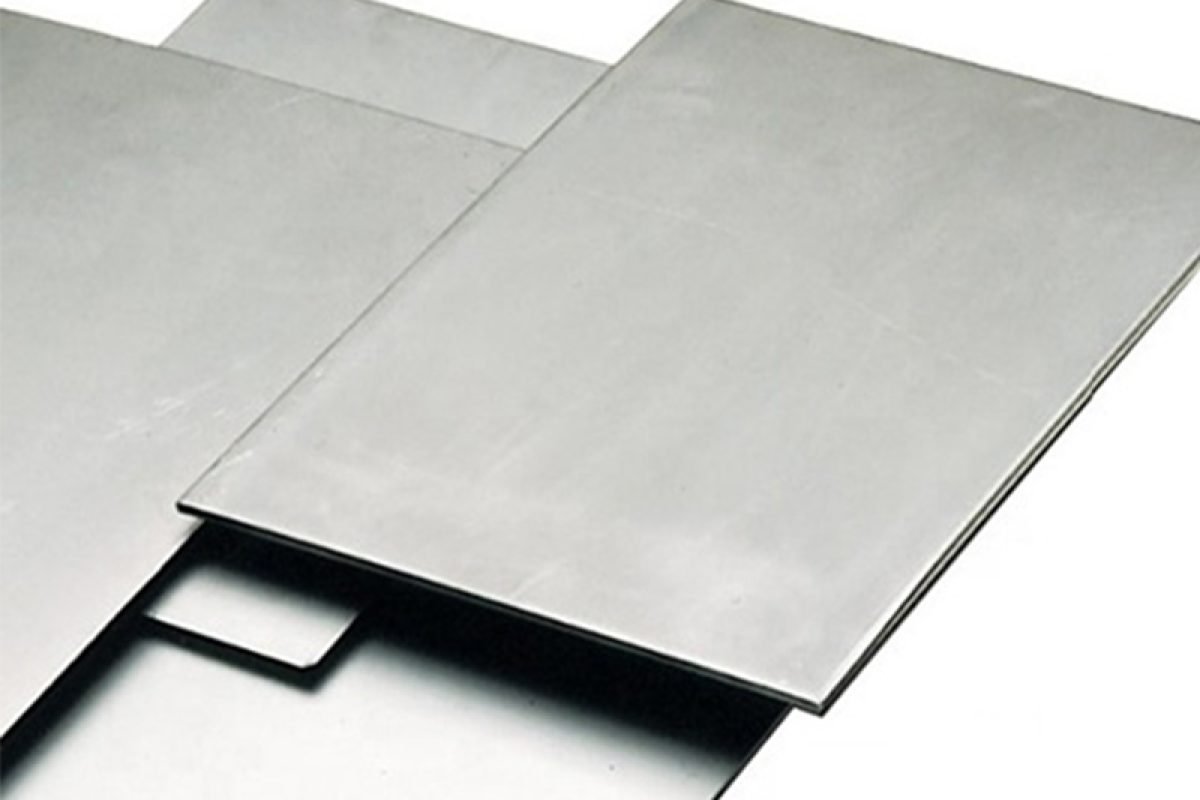

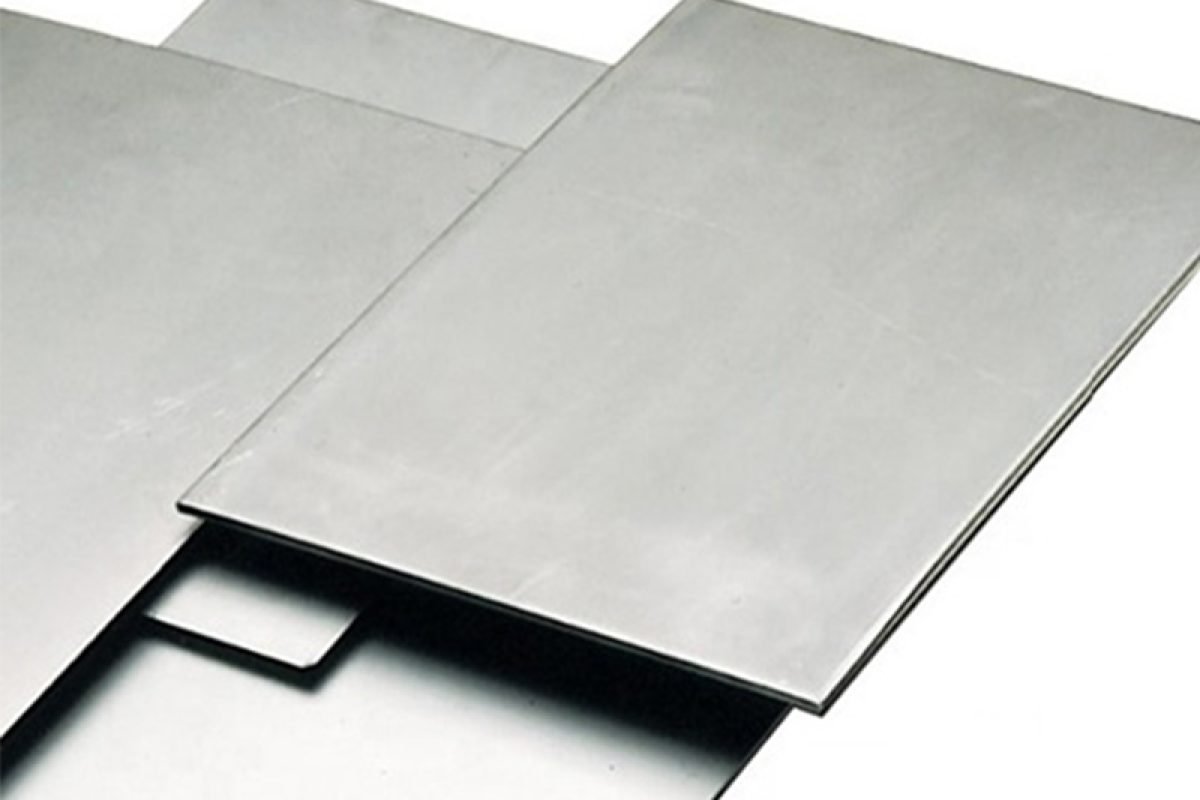

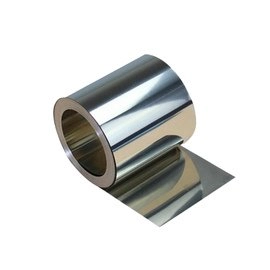

By Material Form – Available in sheets, coils, bars, and tubes for flexible processing.

By Features – From decorative finishes to high strength and corrosion resistance, ensuring the right solution for every project.

With its wide variety, 201 stainless steel provides the perfect balance of performance and cost-effectiveness, making it a smart choice for manufacturers and designers alike.

Stainless steel corrugated sheets are available in the mirror and brushed surface finishes. They excellently work with different techniques, including bending, punching, etc.

Stainless steel corrugated sheets are available in the mirror and brushed surface finishes. They excellently work with different techniques, including bending, punching, etc.

Stainless steel corrugated sheets are available in the mirror and brushed surface finishes. They excellently work with different techniques, including bending, punching, etc.

Stainless steel corrugated sheets are available in the mirror and brushed surface finishes. They excellently work with different techniques, including bending, punching, etc.

201 stainless steel plays an essential role in modern industries due to its unique advantages:

Thanks to this balance of performance, durability, and value, 201 stainless steel has become a popular choice across industries.

The application fields of stainless steel plates are very extensive, and its main features are good corrosion resistance, high strength, elegant appearance, easy cleaning and maintenance, environmental protection and sanitation, and high temperature and low temperature performance. Therefore, stainless steel plates are widely used in many fields such as construction, decoration, industry, medical treatment, food, pharmaceuticals, and automobiles.

| Item | Specification |

|---|---|

| Grade | 201 Stainless Steel |

| Standard | ASTM A240 / A666, JIS G4304 / G4305, DIN EN 10088-2 |

| Chemical Composition (%) | C ≤ 0.15, Mn 5.5–7.5, Si ≤ 1.0, P ≤ 0.060, S ≤ 0.030, Cr 16.0–18.0, Ni 3.5–5.5, N ≤ 0.25 |

| Density | 7.93 g/cm³ |

| Melting Point | 1400–1450 °C |

| Tensile Strength | ≥ 515 MPa |

| Yield Strength (0.2% offset) | ≥ 275 MPa |

| Elongation (%) | ≥ 40% |

| Hardness | ≤ 95 HRB (Annealed) |

| Magnetism | Slightly magnetic after cold working |

| Corrosion Resistance | Moderate (lower than 304, better than carbon steel) |

| Surface Finish | 2B, BA, No.1, No.4, HL, Mirror, etc. |

| Common Forms | Sheet, Plate, Coil, Strip, Pipe, Bar, Wire |

| Applications | Kitchen utensils, sinks, decorative panels, doors, automotive trim, construction, industrial equipment |

As stainless steel sheet suppliers, we at Huaxiao Metal Corporation Limited take great pride in providing high-quality stainless sheet products to our customers. Here are some reasons why we believe you should choose us as your stainless steel sheet suppliers:

In its annealed condition, 201 is generally non-magnetic. However, after cold working (such as bending, stretching, or stamping), it may develop slight magnetism.

In its annealed condition, 201 is generally non-magnetic. However, after cold working (such as bending, stretching, or stamping), it may develop slight magnetism.

In its annealed condition, 201 is generally non-magnetic. However, after cold working (such as bending, stretching, or stamping), it may develop slight magnetism.

Simply fill out the form below as best you can. And don’t sweat the details

In its annealed condition, 201 is generally non-magnetic. However, after cold working (such as bending, stretching, or stamping), it may develop slight magnetism.

In its annealed condition, 201 is generally non-magnetic. However, after cold working (such as bending, stretching, or stamping), it may develop slight magnetism.

In its annealed condition, 201 is generally non-magnetic. However, after cold working (such as bending, stretching, or stamping), it may develop slight magnetism.