Stainless Steel Channel

Stainless Steel Channel Supplier In China

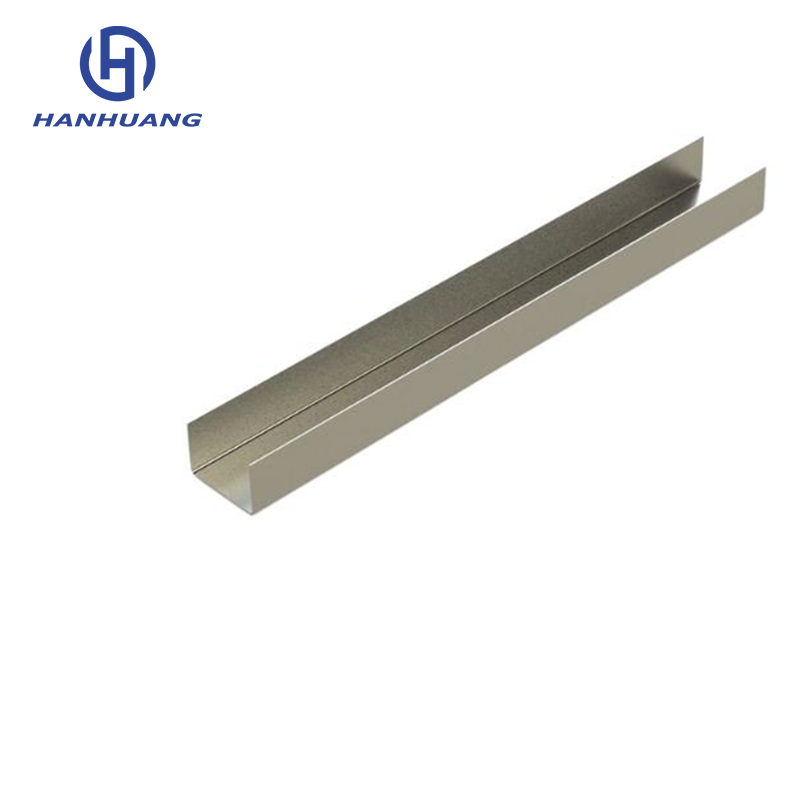

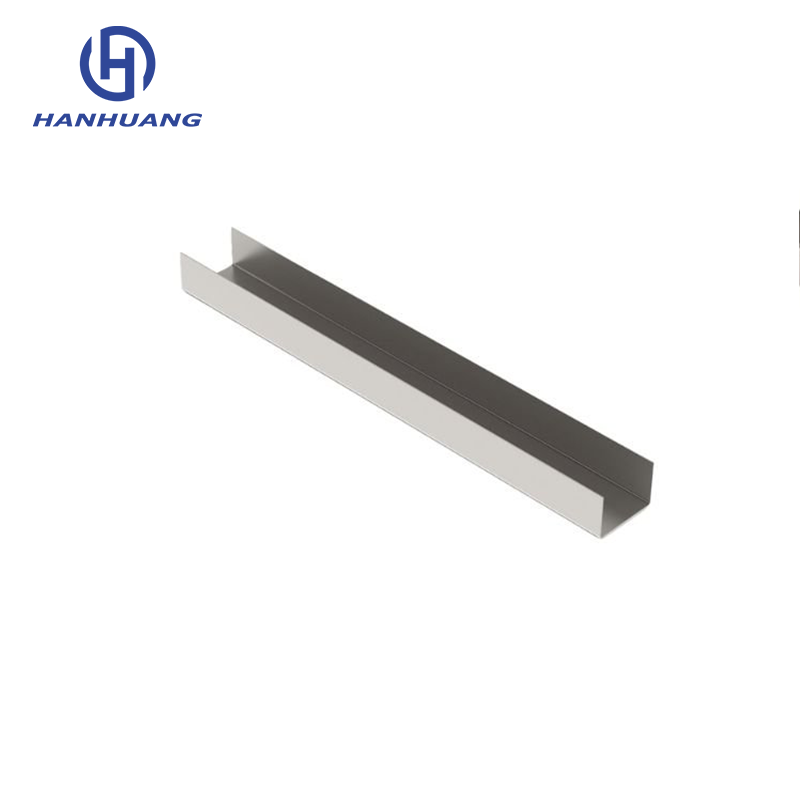

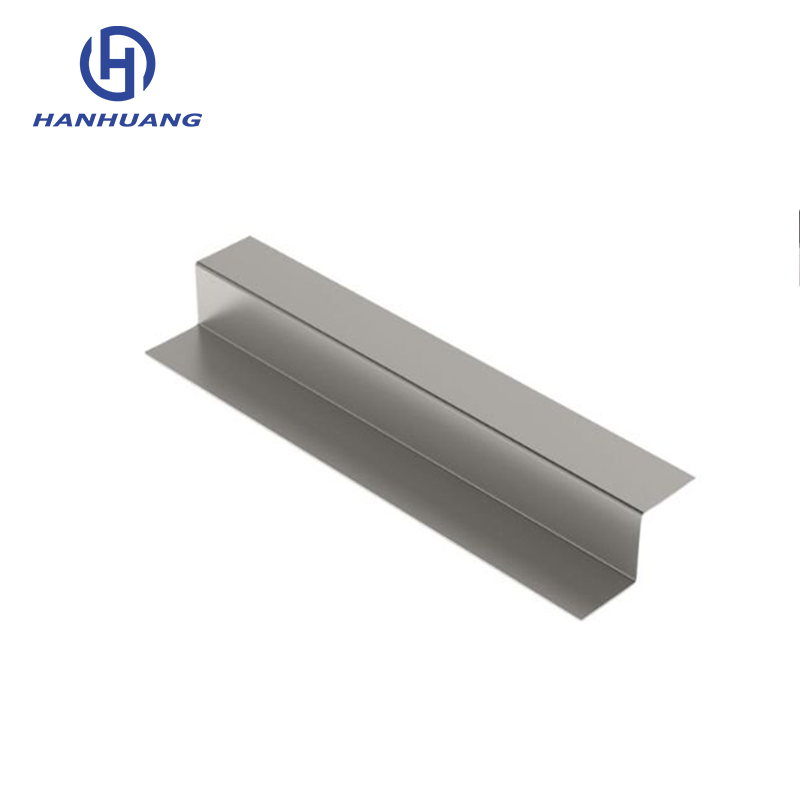

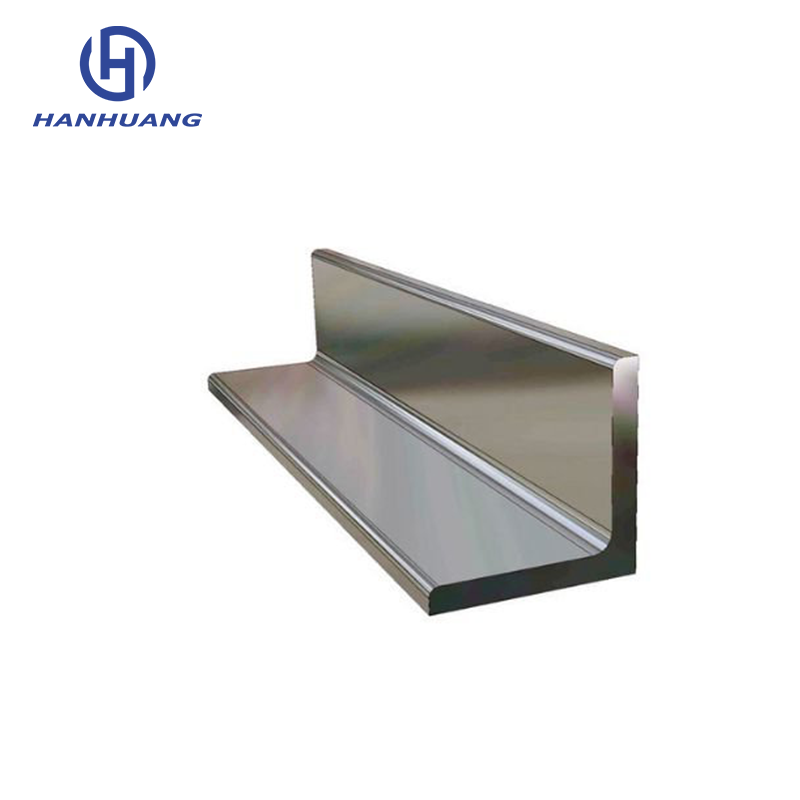

Hanhuang is a professional stainless steel channel manufacturer and supplier, producing high-quality C-Channels, U-Channels, and other structural channels according to ASTM, JIS, and EN standards. Custom channels are available with precise dimensions, thicknesses, and surface finishes to meet industrial and construction project requirements.

Hanhuang specializes in 201, 304, 304L, 310S, 316, 316L, 321, 904L, 2205, 2507, S32750, and S32760 stainless steel channels. These grades offer excellent corrosion resistance, high tensile strength, and long-term durability for industrial, construction, and machinery applications.

| Product Parameters | Hanhuang Stainless Steel Channel |

|---|---|

| Size (Width x Height) | 20mm × 20mm ~ 200mm × 200mm |

| Thickness | 2mm ~ 16mm |

| Surface Finish | Pickling, 8K Mirror, NO.1, NO.4, Hairline, Brushed, Satin, etc. |

| Length | 6000mm or Customized |

| Grade | 201, 304, 304L, 310S, 316L, 321, 904L, 2205, 2507, S32750, S32760, etc. |

Stainless Steel Channel By Grades

SS Channel By Shape

Core Benefits of Stainless Steel Channels

- Corrosion Resistance:Channels are made from 304 and 316 stainless steel, providing excellent resistance to rust, oxidation, and chemical exposure. Suitable for industrial and harsh outdoor environments.

- High Strength & Durability:Designed for heavy load-bearing applications; precision-manufactured channels maintain structural integrity under high stress.

- Easy Maintenance & Hygienic:Smooth surfaces resist staining, ideal for food, pharmaceutical, and hygienic industries.

- Cost-effective & Long-term Use:Durable stainless steel reduces replacement frequency, saving maintenance costs and providing long-term value. All channels comply with ASTM, EN, and JIS standards.

Applications of Stainless Steel Channels

Hanhuang’s stainless steel channels are widely used across various industries:

- Industrial Construction:Structural framing, support beams, and reinforced frameworks, compliant with industrial load standards.

- Machinery & Equipment:Machine frames, conveyor systems, and equipment enclosures, suitable for high-strength industrial machinery.

- Transportation Equipment:Components for vehicles, trailers, and heavy-duty transport structures with corrosion-resistant stainless steel.

- Chemical Industry:Resistant to acids, alkalis, and corrosive chemicals; ideal for tanks, piping supports, and processing equipment.

- Food Processing & Hygienic Applications:Smooth, easy-to-clean channels suitable for food production, handling, and pharmaceutical systems, complying with hygiene standards.

Whether you require custom lengths, heavy-duty channels, or standard stock, our stainless steel channel factory provides solutions to meet the demands of industrial and commercial projects.

What are the differences between 304 and 316 stainless steel channels?

304 stainless steel is suitable for general industrial environments with moderate corrosion exposure. 316 stainless steel contains molybdenum, providing superior resistance to saltwater, chemical corrosion, and harsh outdoor conditions. For high-temperature or highly corrosive applications, duplex or 310S stainless steel channels may be preferred.

Can Hanhuang provide custom stainless steel channels?

Yes. Hanhuang specializes in custom manufacturing, including specific lengths, sizes, thicknesses, and finishes. Simply provide your specifications or drawings, and our engineers will produce channels tailored to your needs.

What is the typical lead time for orders?

Standard channels are available from stock. Custom orders usually require 2–4 weeks, depending on complexity and quantity.