Stainless Steel for Marine & Offshore

Hanhuang stainless steel is widely used in demanding marine and offshore applications where corrosion resistance and structural reliability are critical. It serves in shipbuilding for hull structures and superstructures, offshore oil and gas platforms, subsea pipelines and fittings, and marine hardware such as fasteners and pumps. Additionally, Hanhuang stainless steel supports desalination and seawater treatment systems, ensuring long-term performance under constant saltwater exposure and high mechanical stress.

Stainless Steel for Marine & Offshore In China

Stainless Steel Shape You Can Choose

Corrosion Resistance and Maintenance

In marine environments, stainless steel faces challenges like pitting, crevice, and stress corrosion cracking caused by chlorides and seawater exposure. Hanhuang applies advanced surface treatments such as passivation, polishing, and protective coatings to enhance corrosion resistance. Regular cleaning and maintenance further extend the material’s lifespan, maintaining appearance and functionality even in harsh offshore conditions. These measures ensure long-term reliability and minimal downtime for marine structures and components.

Common Stainless Steel Grades Used in Marine & Offshore

Hanhuang provides a full range of stainless steel grades engineered for the harsh marine and offshore environments. Austenitic grades such as 304, 304L, 316, 316L, and 317L offer excellent corrosion resistance and weldability. Duplex and Super Duplex grades like 2205, 2507, and SAF 2707HD combine superior strength with outstanding resistance to chloride-induced corrosion. For highly aggressive conditions, high-alloy grades including 904L, Alloy 20, and 6Mo (UNS S31254) deliver exceptional durability. Martensitic grades such as 410 and 420 are suited for shafts and mechanical parts, while ferritic grades 444 and 446 provide economical corrosion protection for various structural and decorative applications.

Common Stainless Steel Product Forms for Marine & Offshore

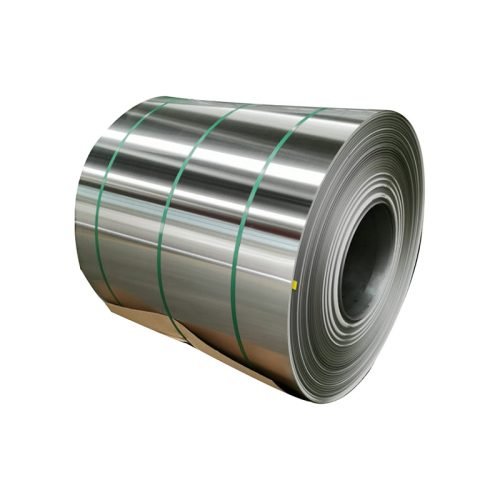

Hanhuang supplies a wide range of stainless steel product forms for shipbuilding, offshore construction, and marine systems. Options include plates and sheets for structural fabrication, pipes and tubes for seawater and chemical transport, bars, rods, and wire for fasteners and anchors, and fittings, flanges, and valves for offshore piping systems. Coils and strips are available for flexible applications, along with custom-machined parts designed for marine equipment and hardware.

Which stainless steel grades are commonly used in marine and offshore applications?

In marine and offshore environments, commonly used stainless steel grades include 304 and 304L for general structural components, 316 and 316L for parts exposed to seawater or humid conditions, 317L for enhanced corrosion resistance in aggressive marine environments, 321 and 347 for high-temperature components, duplex 2205 for applications requiring high strength and excellent resistance to pitting and crevice corrosion, super duplex 2507 for extremely corrosive offshore environments, 904L for highly acidic conditions, and titanium-stabilized grades like 321H or 347H for long-term high-temperature service.

Why is stainless steel preferred in marine and offshore engineering?

How do environmental conditions influence the choice of stainless steel in marine applications?

Are surface treatments necessary for stainless steel in marine environments?

Yes, surface treatments such as pickling, passivation, and electropolishing enhance the protective oxide layer, improve resistance to pitting and crevice corrosion, and reduce fouling. For offshore applications, these treatments help ensure long-term durability and reduce maintenance requirements.