Hanhuang Stainless Steel Processing & Custom Fabrication Services

At Hanhuang, we provide complete stainless steel processing and customization services to meet a wide range of industrial, architectural, and commercial requirements.

Our advanced equipment supports every stage of stainless steel preparation—from flattening and cutting to film lamination and surface cleaning—ensuring top precision, consistency, and surface integrity.

| Processing Step | Professional Description |

|---|---|

| Leveling / Decoiling & Cutting | Uncoiling stainless steel rolls and cutting them into flat sheets. |

| Slitting | Cutting wide coils into narrower strips to meet different width requirements. |

| Oil Coating / Oil Film Application | Preventing oxidation and rust during storage and transport. |

| Coil Rewinding (Large to Small) | Adjusting coil length, weight, or packaging dimensions. |

| Piercing / Basic Drilling | Pre-punching holes for structural or assembly purposes. |

| Cut-to-Length (CTL) | Cutting coils into sheets of specified length. |

| Flattening / Precision Leveling | Ensuring flat sheets without warp or coil set. |

| Trimming | Removing uneven edges or burrs for clean edges. |

| Film Laminating | Protecting the surface from scratches during transport and processing. |

| Deburring / Chamfering | Improving edge quality and safety by removing sharp edges or burrs. |

| Coil Splitting & Weighing | Dividing coils according to customer specifications and precise weighing. |

| Surface Cleaning | Removing oil, dust, or residue to improve subsequent surface treatment quality. |

Stainless Steel Shape You Can Choose

Full-Range Stainless Steel Processing Capabilities

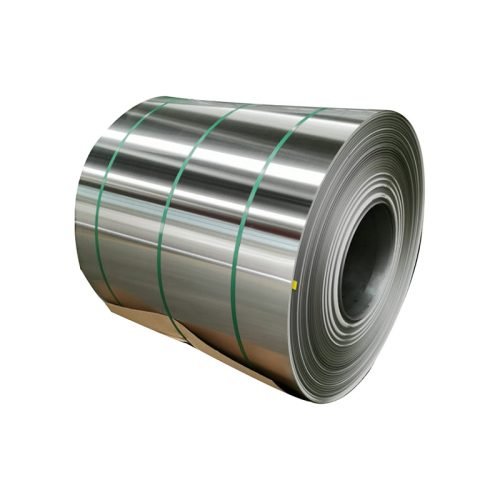

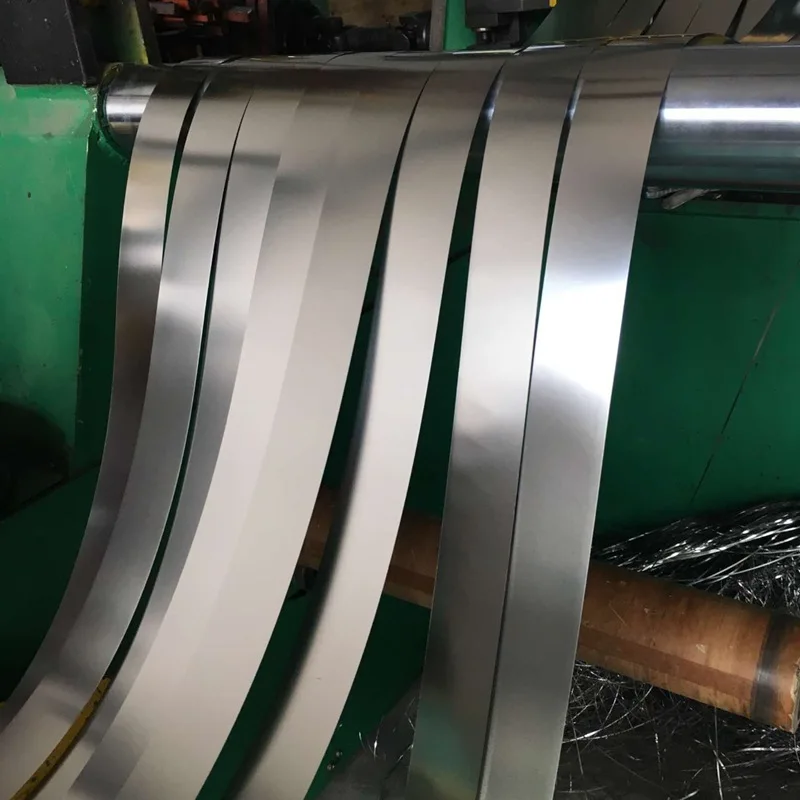

Slitting

Hanhuang provides high-precision stainless steel slitting services to deliver strips with consistent width and clean edges. Our slitting machines handle various thicknesses and grades of stainless steel, ensuring uniform width control for tubes, appliances, and construction parts. By maintaining tight dimensional tolerances and burr-free edges, we ensure each slit coil meets your exact requirements. This process supports efficient downstream fabrication and reduces waste, making it a vital part of stainless steel processing and customization.

Leveling / Decoiling & Cutting

Our stainless steel leveling and decoiling process ensures sheets are perfectly flat, stress-free, and ready for precision fabrication. Using advanced equipment, we uncoil stainless steel rolls, level them, and cut to specified sizes with tight tolerances. This process eliminates coil set and waviness, producing smooth, even surfaces ideal for forming, welding, or surface finishing. Hanhuang’s skilled technicians maintain consistent accuracy, providing customers with reliable, ready-to-use stainless steel materials for various industrial and architectural applications.

Oil Coating / Oil Film Application

To preserve surface integrity and prevent oxidation, Hanhuang applies a uniform protective oil film to all stainless steel products. This process minimizes corrosion during storage, shipping, or further fabrication. The applied coating also prevents fingerprints, moisture stains, and contamination, maintaining a clean, professional finish. Our oil coating service is an essential part of stainless steel surface protection, especially for polished or brushed materials destined for decorative, food-grade, or precision industrial uses.

Rewinding /Large to Small Rolls

Hanhuang’s rewinding service converts master coils into smaller rolls for specific handling or packaging needs. With precise tension control, we ensure uniform density, smooth edges, and scratch-free surfaces for efficient storage, transport, and downstream processing.

Piercing / Basic Drilling

Hanhuang provides precision piercing and drilling for stainless steel sheets and parts, delivering clean, accurate holes for quick assembly and structural use. Advanced equipment ensures distortion-free edges and reliable, ready-to-fabricate results that save time and enhance final alignment and durability.

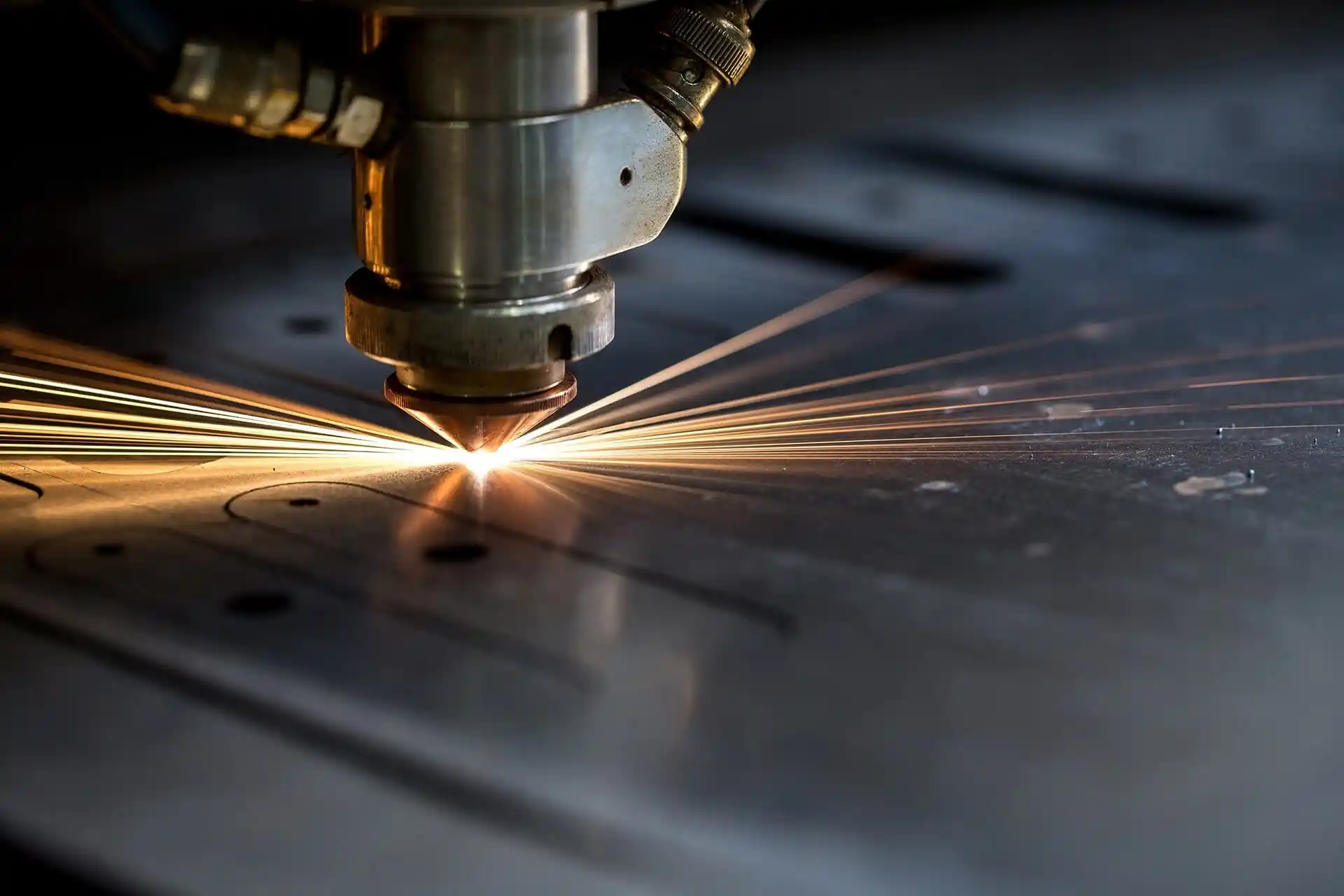

Flattening / Precision Leveling

Our precision leveling service delivers stainless steel sheets with superior flatness and uniform thickness. Using advanced leveling machines, internal stress and coil memory are eliminated to ensure smooth, stable material for tight-tolerance applications such as fabrication, laser cutting, and finishing. Each sheet meets the highest standards of consistency, reliability, and performance.

Cut-to-Length (CTL)

The cut-to-length service provides stainless steel sheets precisely sized to your requirements. Automated CTL lines ensure accurate lengths, straight edges, and smooth surfaces while eliminating manual cutting errors. This process maintains tight tolerances across various thicknesses and finishes, delivering stainless steel sheets ready for forming, welding, or assembly in industrial, decorative, and structural applications.

Trimming

Edge trimming is a key step in ensuring stainless steel sheets and strips have clean, uniform, and burr-free edges. Hanhuang’s trimming process removes imperfections from coil edges and prepares materials for further fabrication or finishing. Our high-precision trimming equipment maintains consistent width and minimizes waste. The result is a perfectly dimensioned stainless steel product with enhanced appearance and usability—ready for cutting, welding, or decorative use in any industry.

Deburring / Chamfering

After cutting or trimming, Hanhuang performs deburring and chamfering to remove sharp edges and metal burrs. This process improves handling safety, enhances product appearance, and ensures compatibility with precision assemblies. We use specialized equipment to achieve smooth, uniform edges across stainless steel sheets and parts. Deburred materials not only look better but also reduce wear on tools and improve downstream production efficiency—an essential part of high-quality stainless steel processing.

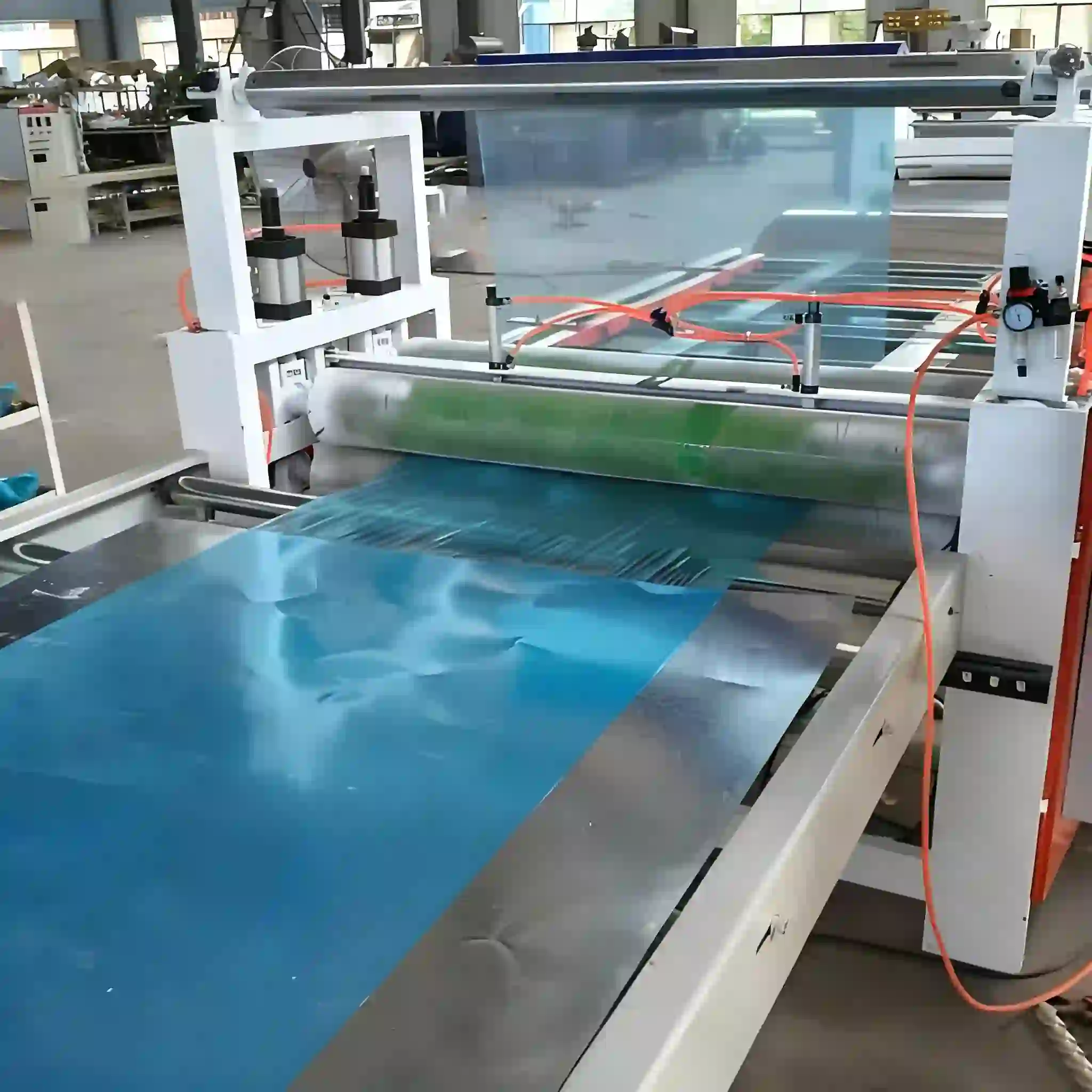

Film Laminating

Protective film lamination safeguards stainless steel surfaces from scratches, dirt, and damage during transport or processing. Hanhuang applies PE or PVC protective films suited to different surface finishes such as mirror, brushed, or BA. The film ensures the surface remains clean and flawless throughout handling and fabrication. Our laminating service enhances both protection and presentation, making it essential for stainless steel used in decorative and precision applications.

Splitting & Weighing

Our stainless steel splitting and weighing service ensures every batch is accurately divided and labeled according to customer specifications. We use advanced measurement and tension-control systems to maintain consistency across multiple rolls or sheets. This process improves logistics, simplifies inventory tracking, and ensures precise order fulfillment. Each stainless steel package from Hanhuang is carefully weighed, documented, and quality-checked before shipment.

Surface Cleaning

Surface cleaning is the final step to ensure each stainless steel product leaves our facility in perfect condition. We remove oil, dust, and residues from processing using safe and efficient cleaning techniques. This step improves surface appearance, enhances adhesion for further coating or finishing, and ensures compliance with hygiene and quality standards. Hanhuang’s stainless steel surface cleaning guarantees materials are ready for direct use in industrial, architectural, or consumer applications.