Stainless Steel Quality Inspection

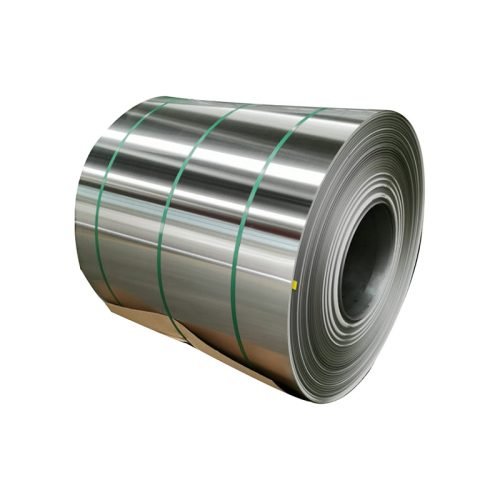

At Hanhuang, we understand that maintaining high-quality stainless steel is essential for durability, performance, and safety across industrial applications. A thorough stainless steel quality inspection ensures every sheet, coil, or component meets international standards and client requirements.

- High Durability: Manufactured from high-quality alloys for long-lasting performance in demanding industrial environments.

- Outstanding Corrosion & Wear Resistance: Scratch-resistant, rust-proof, and chemically resistant, ensuring reliable operation over time.

- Customizable Solutions: Tailored stainless steel sheets and components available to meet specific project requirements.

- Cost-Effective: Delivers premium quality and durability at competitive prices, helping control project costs.

Hanhuang Stainless Steel Quality Inspection

Stainless Steel Shape You Can Choose

Why Stainless Steel Quality Inspection Matters

At Hanhuang, we understand that maintaining high-quality stainless steel is essential for durability, performance, and safety across industrial applications. A thorough stainless steel quality inspection ensures every sheet, coil, or component meets international standards and client requirements.

• Ensuring Durability and Longevity: Proper inspection guarantees structural stability for long-term use in demanding environments.

• Corrosion Resistance and Safety: By testing chromium levels and protective coatings, we confirm that products are non-toxic stainless steel suitable for food, medical, and industrial use.

• Maintaining Structural Integrity: Our workflow verifies mechanical properties, surface finishes, and dimensional accuracy.

• Cost Efficiency: Accurate inspections reduce rework, minimize maintenance costs, and extend the lifecycle of every product.

Methods of Stainless Steel Quality Inspection

We combine traditional techniques with advanced instrumentation:

• Visual Inspection: Checks for scratches, dents, and surface defects. Guides clients in how can you tell if something is stainless steel without sophisticated equipment.

• Dimensional and Tolerance Checks: Precise measurements ensure how to tell stainless steel from steel regarding thickness, width, and flatness.

• Non-Destructive Testing (NDT):

Magnetic Particle Testing

Ultrasonic Testing

Dye Penetrant Testing

• Corrosion Resistance Testing: Salt spray and immersion tests confirm suitability for harsh environments, useful for non toxic stainless steel cooking utensils or marine applications.

• Flexibility and Strength Tests: Ensures products meet bending and tensile specifications.

• Heat Treatment Verification: Confirms consistent hardness and microstructure.

Coating and Plating Inspection: Checks adhesion and uniformity for passivation or plating layers.

Our process guarantees traceable, repeatable, and documented stainless steel quality inspections:

1. Raw Material Sourcing: All materials come with verified stainless steel test certificates.

2. Supplier Verification: Only ISO/ASTM-compliant suppliers are accepted.

3. Step-by-Step Inspection: Each stage, from cutting to finishing, is inspected to minimize defects.

4. Documentation: Every batch is accompanied by a detailed stainless steel quality report for full traceability.

Quality Assurance Process at Hanhuang

How can I tell if stainless steel is high-quality?

By verifying grade, surface finish, chemical composition, and mechanical properties using professional stainless steel quality inspections.

Can inspections prevent corrosion failures?

What standards do Hanhuang follow?

How often should inspections be conducted?

At every production stage and prior to shipment to guarantee consistent stainless steel high quality.