Stainless Steel Surface Treatment by Hanhuang

At Hanhuang, we specialize in providing comprehensive stainless steel surface treatment solutions that elevate the performance, longevity, and appearance of stainless steel across industrial, commercial, and architectural applications. Whether you require a functional finish for machinery components or a high-precision decorative finish, our expert team delivers tailored solutions for every project.

Proper surface treatment is crucial to unlock the full potential of stainless steel. It improves:

- Corrosion resistance – Protects against rust, pitting, and environmental damage.

- Durability – Enhances wear and scratch resistance for long-term performance.

- Aesthetic quality – Achieves the precise look required for both industrial and architectural projects.

From large-scale industrial components to decorative panels, choosing the right surface finish ensures that your stainless steel meets both performance and design requirements.

Stainless Steel Surface Treatment by Hanhuang

Stainless Steel Shape You Can Choose

Stainless Steel Surface Treatment Methods

Mechanical Finishes

Surface Treatment:Polishing

Polishing stainless steel transforms its surface into a smooth, reflective finish that enhances both aesthetics and functionality. At Hanhuang, we apply precision polishing techniques to achieve mirror-like or satin finishes, tailored to industrial or decorative needs. Polishing not only improves visual appeal but also reduces surface imperfections, minimizing potential sites for corrosion or contamination. This makes it ideal for high-end architectural panels, kitchen equipment, and machinery components. Our team evaluates each stainless steel grade to determine the optimal polishing process, ensuring consistent quality and long-lasting durability, meeting both performance and visual standards required by professional applications.

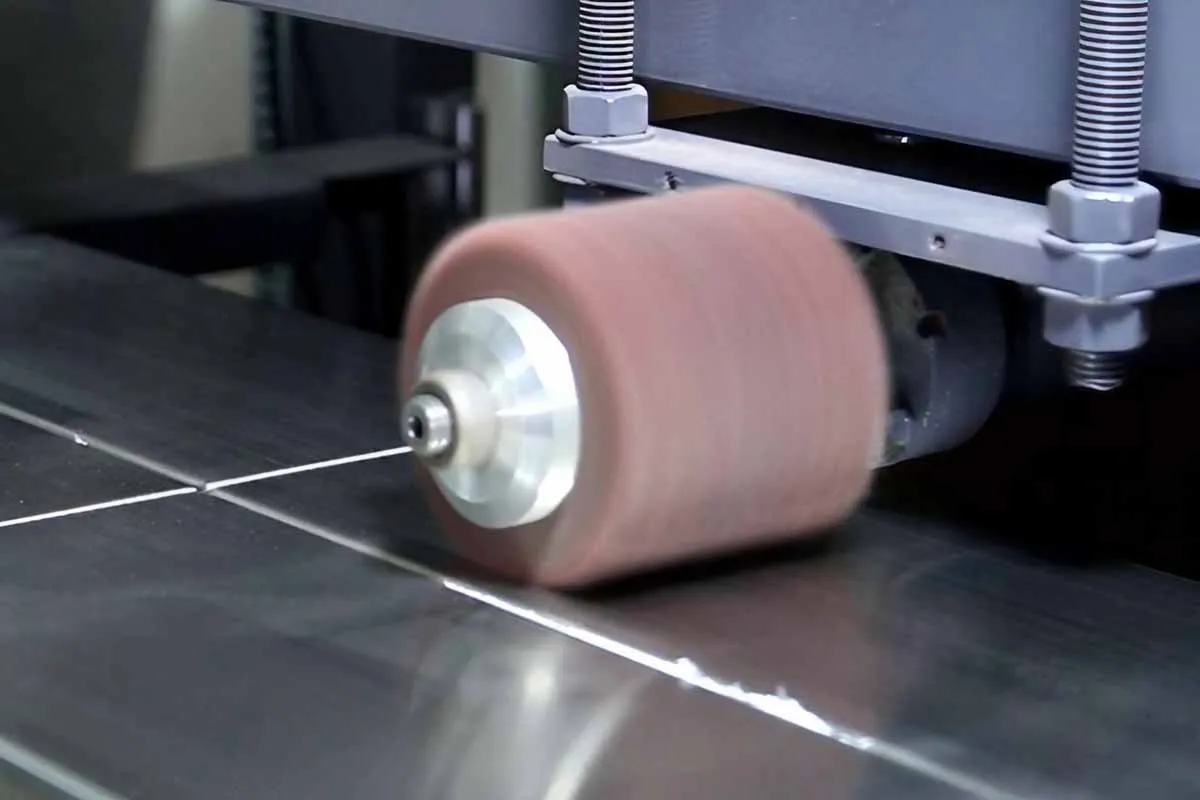

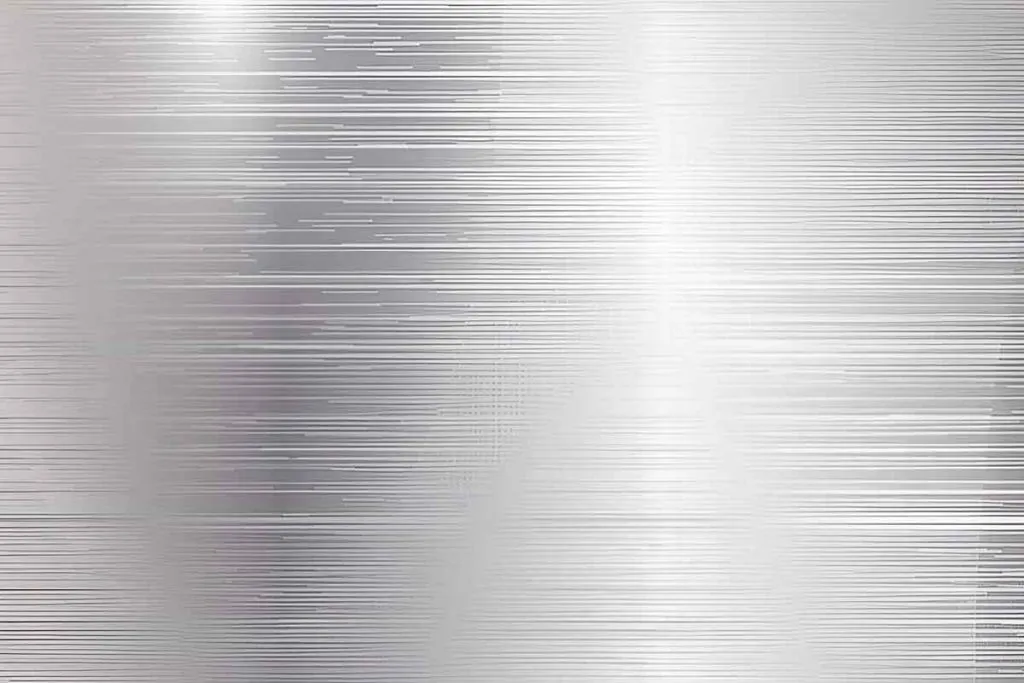

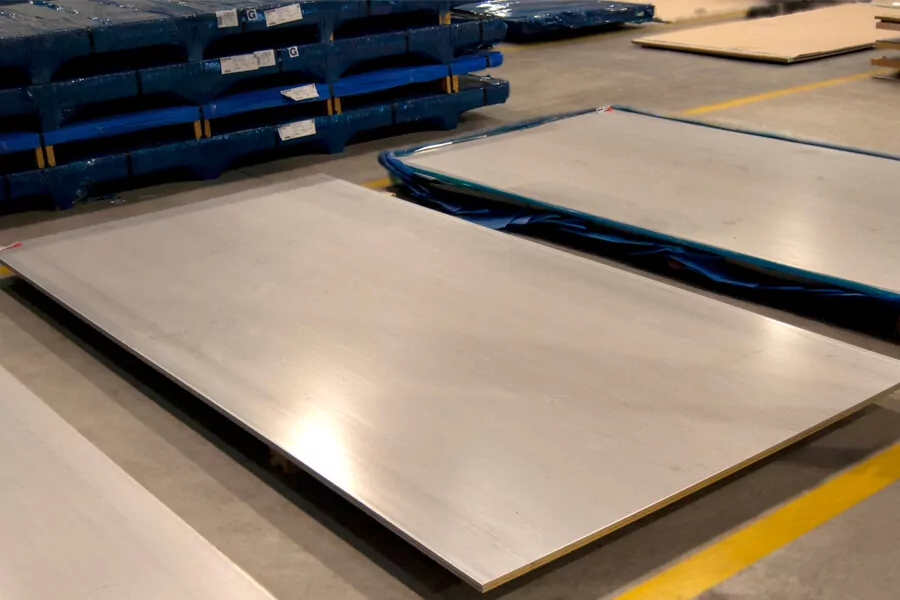

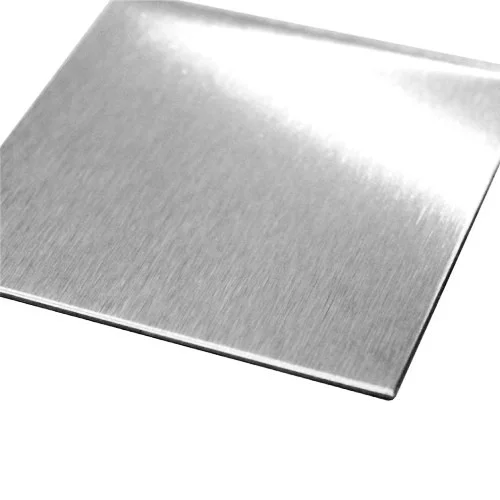

Surface Treatment:Brushing

Brushing creates a uniform, textured surface with subtle directional grain, combining durability and aesthetic appeal. Hanhuang offers brushed finishes such as No. 4 and No. 6, perfect for industrial machinery, elevators, architectural panels, and kitchen surfaces. The brushing process removes minor imperfections while maintaining the metal’s inherent corrosion resistance. Its controlled texture reduces glare and enhances visual consistency across large surfaces. Each brushed finish is carefully executed to meet industrial standards, ensuring smooth operation, easy maintenance, and long-term durability. Brushing also provides an ideal base for additional surface treatments or coatings, offering versatile solutions for a wide range of stainless steel applications.

Surface Treatment:Passivation

Passivation is a critical chemical treatment that enhances corrosion resistance by forming a protective oxide layer on stainless steel surfaces. Hanhuang employs advanced passivation methods to remove free iron and contaminants, ensuring the steel achieves maximum durability in harsh environments. This process is essential for industrial equipment, food processing machinery, chemical handling systems, and marine applications. By strengthening the naturally protective chromium oxide layer, passivation extends service life and maintains a pristine, clean surface. Our controlled process guarantees compliance with international standards, providing clients with stainless steel components that withstand corrosion, wear, and demanding operational conditions.

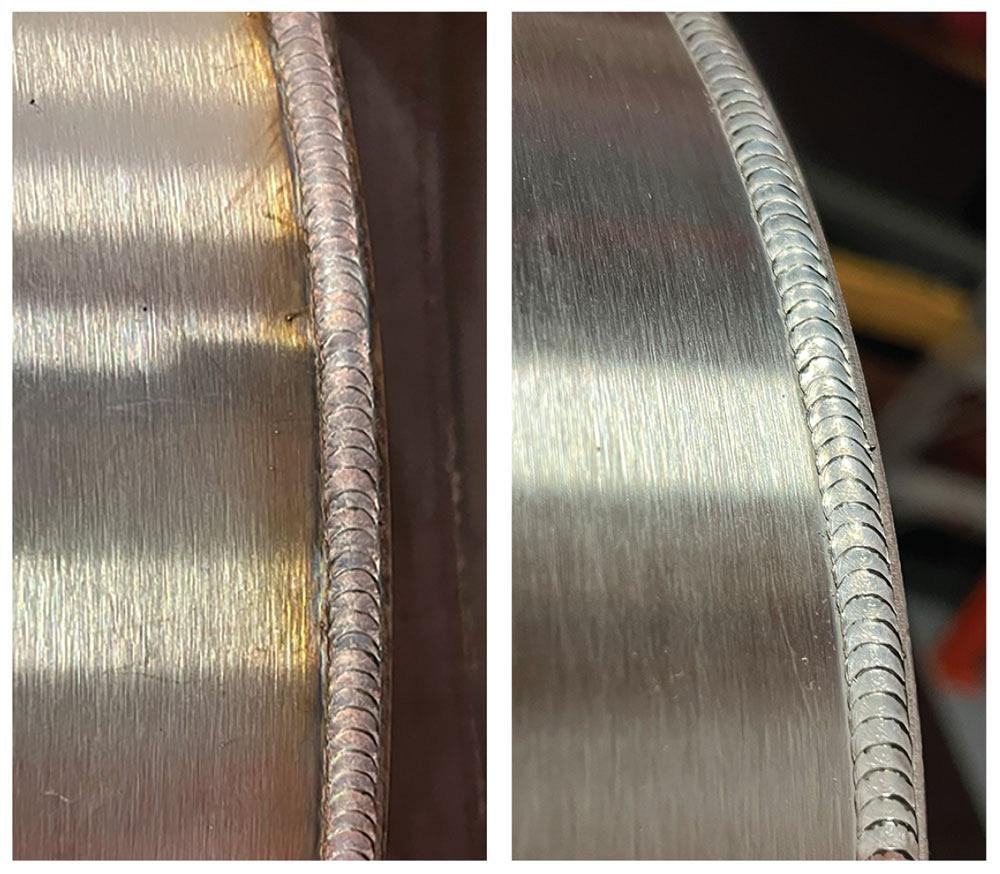

Surface Treatment:Pickling

Pickling involves acid treatment to remove surface scale, rust, and other impurities from stainless steel, restoring its clean, smooth appearance. At Hanhuang, our pickling process prepares steel for subsequent finishing or enhances its corrosion resistance and aesthetic quality. Ideal for post-fabrication or welding applications, pickled surfaces ensure the removal of contaminants that can lead to premature oxidation. This treatment is widely used in industrial, architectural, and food-grade applications, guaranteeing long-term durability and uniform performance. Hanhuang carefully controls acid concentration, temperature, and exposure time, delivering consistently high-quality results that meet both professional and regulatory standards.

Surface Treatment:Electroplating

Electroplating deposits a thin layer of metal onto stainless steel surfaces, enhancing corrosion protection, conductivity, and visual appeal. Hanhuang provides precise electroplating solutions to achieve gold, nickel, chrome, or other metallic finishes, tailored to client specifications. This method not only improves durability in challenging environments but also enables decorative applications for architectural elements, furniture, and industrial components. Electroplated surfaces maintain excellent adhesion and long-lasting performance when executed with proper surface preparation. Our team ensures consistent thickness, uniform coverage, and compliance with industrial standards, delivering stainless steel products that combine enhanced functionality with premium aesthetics.

Surface Treatment:Electroplating

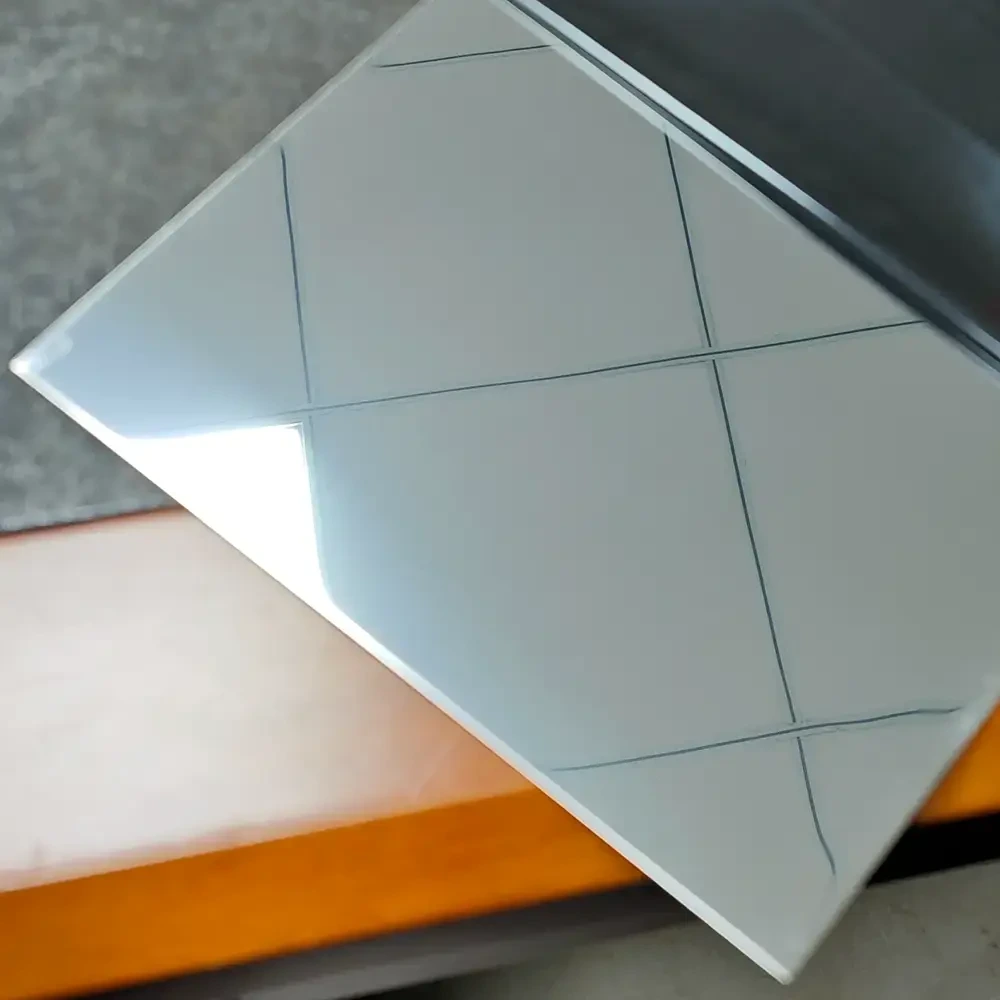

A mirror finish produces a highly reflective, smooth surface ideal for decorative, architectural, and premium industrial applications. Hanhuang applies precise mechanical and chemical finishing techniques to achieve a flawless, reflective effect. This finish not only enhances aesthetics but also reduces surface roughness, minimizing areas for dirt and corrosion. Mirror-finished stainless steel is widely used in elevators, kitchen equipment, decorative panels, and high-end appliances. Our team ensures consistent reflection and surface uniformity across each piece, meeting stringent industrial standards. With careful attention to material grade, polishing sequence, and protective processes, Hanhuang delivers stainless steel surfaces that combine visual perfection with long-term durability.

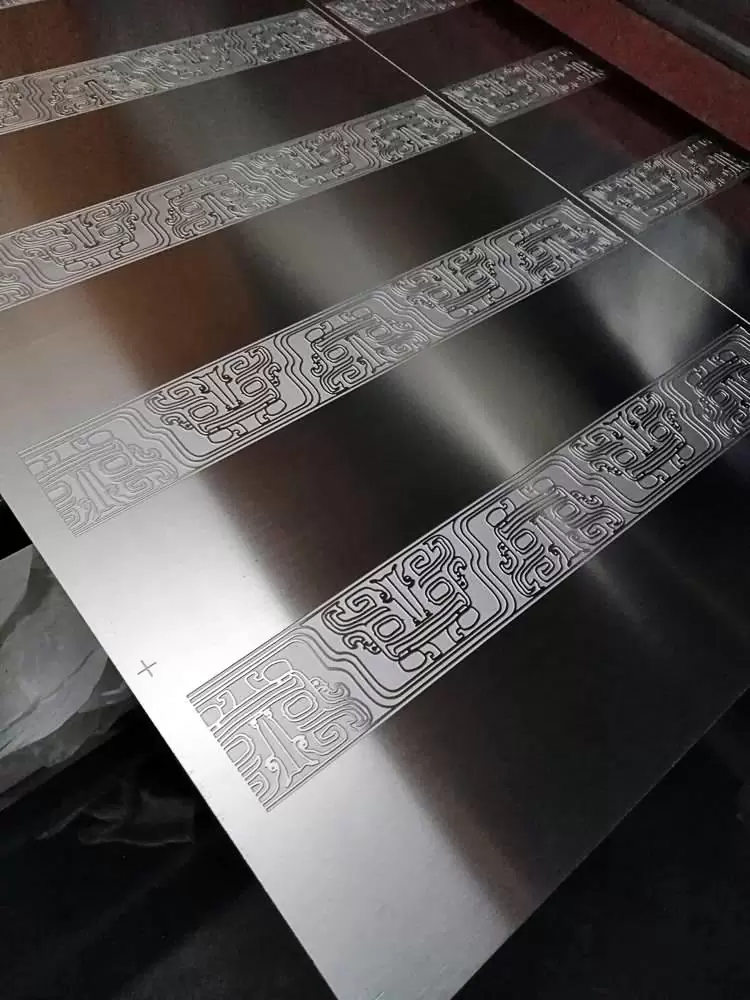

Surface Treatment:Etching

Etching is a specialized process that creates patterns, textures, or functional surface modifications on stainless steel. Hanhuang uses chemical or laser etching to produce precise, permanent designs, enhancing both aesthetics and performance. Etched surfaces can serve decorative purposes, improve grip, or provide visual cues for industrial applications. Our team carefully controls etching depth, pattern consistency, and chemical exposure to ensure uniform, high-quality results. This method is suitable for architectural panels, signage, control panels, and machinery components, combining customized design with the inherent corrosion resistance and durability of stainless steel.

Mill Finishes

No. 1 Finish Stainless Steel

2D Finish Stainless Steel

2B Finish Stainless Steel

BA Finish Stainless Steel

No. 3 Finish Stainless Steel

No. 4 Finish Stainless Steel

No.7 Finish Stainless Steel

No. 8 Finish Stainless Steel

| Finish | Description |

|---|---|

| No. 1 Finish | Rugged and durable, suitable for heavy-duty industrial use |

| 2D Finish | Cold rolled, annealed, and pickled for smooth, functional surfaces |

| 2B Finish | Matte, smooth, and machine-friendly finish |

| BA Finish | Bright reflective finish, suitable for precision projects |

| No. 3 Finish | Intermediate polish (100–120 grit) with controlled surface texture |

| No. 4 Finish | Standard brushed finish (150–180 grit), versatile and widely used |

| No. 7 Finish | Pre-mirror polish, near-reflective surface |

| No. 8 Finish | Full mirror finish for decorative and premium applications |

Specialty & Custom Finishes

For projects with unique requirements, we offer customized finishes—balancing decorative appeal and functional performance. Hanhuang can tailor surface treatment to meet industry-specific standards and aesthetic demands.

Why Choose Hanhuang

- Expertise Across Multiple Techniques – Hanhuang masters an extensive range of stainless steel surface treatment processes, including polishing, brushing, passivation, pickling, electroplating, mirror finishing, and more. Our experienced engineers ensure every finish meets the required functional and aesthetic standards for your application.

- High-Quality Standards – We strictly follow ISO and ASTM standards throughout every production step, from raw material preparation to final inspection. Each treated surface undergoes precision testing for corrosion resistance, adhesion, and durability, guaranteeing consistency and long-term performance.

- Customized Solutions – Hanhuang provides fully tailored surface treatment solutions designed for industrial, commercial, and architectural projects. Whether you need enhanced reflectivity, improved resistance, or a specific texture, we adapt our methods to meet your unique technical requirements.

- Proven Track Record – With years of experience serving clients in construction, machinery, food processing, and marine industries, Hanhuang has built a reputation for quality, reliability, and on-time delivery. Our treated stainless steel components perform under the most demanding conditions worldwide.

What is the best way to polish stainless steel?

Polishing method depends on grade, desired finish, and application; we provide expert recommendations for optimal results.

How do I passivate stainless steel?

What is the difference between matte, brushed, and mirror finishes?

Can all metals be electroplated?

Not all metals are suitable; our team evaluates compatibility to ensure adhesion, durability, and performance.

How do I maintain treated stainless steel for longevity?

Follow proper cleaning, avoid abrasive tools, and periodically inspect for environmental wear to preserve finish and protection.